You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pergola build

- Thread starter ihadablackdog

- Start date

ihadablackdog

Senior member

Thank-you. Just spent a few minutes trying to understand that, but I think I do now.

I think that would be a good solution as the diamond shape would need to be carved out with a chisel because the jigsaw or circular saw won’t do it, but a flat end on the cut is fine.

I’ll think about cutting the inside square as well cos that will make it easy and probably would never notice anyway.

I think that would be a good solution as the diamond shape would need to be carved out with a chisel because the jigsaw or circular saw won’t do it, but a flat end on the cut is fine.

I’ll think about cutting the inside square as well cos that will make it easy and probably would never notice anyway.

ihadablackdog

Senior member

Only drawback I can see is access to that end, that’s on the corner of the patio and the grass is uneven, had to balance on dodgy make shift supports for the step ladder to screw the beams in.

Think I need a longer step ladder anyway, so I can get above the height of the rafters because I’m screwing them into the front and side beams and then putting the strapping across the top (which is 1x2 pt batons, apparently with a slight green tinge from the treatment, so might need to stain that so it doesn’t stand out too much).

So should be able to do it from above leaning over the post from inside.

Think I need a longer step ladder anyway, so I can get above the height of the rafters because I’m screwing them into the front and side beams and then putting the strapping across the top (which is 1x2 pt batons, apparently with a slight green tinge from the treatment, so might need to stain that so it doesn’t stand out too much).

So should be able to do it from above leaning over the post from inside.

ihadablackdog

Senior member

Ordered a 12 way combination ladder thing that bends in all sorts of ways (hopefully it doesn’t bend under my weight).

Hopefully be able to get a decent position to work from.

Hopefully be able to get a decent position to work from.

ihadablackdog

Senior member

Good day yesterday….got the rest of the rafters cut to length and all except 4 are notched. Although I’m not happy with the first one that I notched so might redo that one, and have to tweak the middle notch on most so that the front one sits totally flush.

Did as you suggested and cut the 45 degree corner at 45 degrees allowing for a flat edge to the notch.

Got some batons on Friday (PT unfortunately, but hopefully they will blend in) so there is a chance I could finish the notching and install the batons today.

(photos not in order, too fiddly to change on an iPhone)

Did as you suggested and cut the 45 degree corner at 45 degrees allowing for a flat edge to the notch.

Got some batons on Friday (PT unfortunately, but hopefully they will blend in) so there is a chance I could finish the notching and install the batons today.

(photos not in order, too fiddly to change on an iPhone)

ihadablackdog

Senior member

Nictrix said:Thats exactly what I meant about chamfering the end, glad it went well and it looks great.

Yeah, worked well and much neater than I would’ve ended up with. Thanks for the suggestion.

ihadablackdog

Senior member

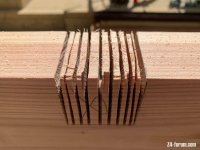

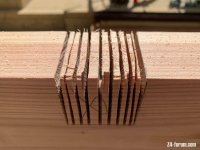

So this is how I made my notches:

1. Mark with pencil

2. Cut edges with hand saw to make them neat (managed to get all cuts in line).

3. Make multiple cuts with circular saw

4. Whack with hammer

5. Tidy up with circular saw in sideways motion.

(The 45 degree ones were the same, just cutting on the angle).

1. Mark with pencil

2. Cut edges with hand saw to make them neat (managed to get all cuts in line).

3. Make multiple cuts with circular saw

4. Whack with hammer

5. Tidy up with circular saw in sideways motion.

(The 45 degree ones were the same, just cutting on the angle).

ihadablackdog

Senior member

ihadablackdog

Senior member

FINISHED!!!!!

(I will add some corner braces at some point, but just for show, it’s sturdy without them).

Put the strapping on tonight. Not happy with the wood, it’s PT 2x1 and I guess the colour doesn’t match, but hoping the lot will weather and it won’t be so obvious, but then most people wouldn’t care or notice anyway).

Got to say thank you to Pondrew, Chippie, Nicktrix for all your help, advice and support, it really helped me do a much better job than I would’ve done otherwise.

Will put the seating back tomorrow and crack open that Thatchers that I promised myself 2 weeks ago

Final screw!!!!

(I will add some corner braces at some point, but just for show, it’s sturdy without them).

Put the strapping on tonight. Not happy with the wood, it’s PT 2x1 and I guess the colour doesn’t match, but hoping the lot will weather and it won’t be so obvious, but then most people wouldn’t care or notice anyway).

Got to say thank you to Pondrew, Chippie, Nicktrix for all your help, advice and support, it really helped me do a much better job than I would’ve done otherwise.

Will put the seating back tomorrow and crack open that Thatchers that I promised myself 2 weeks ago

Final screw!!!!

Cracking job mate, if you don’t mind me asking what was the total price of materials?

ihadablackdog

Senior member

Too scared to add it up to be honest!

Timber was about £950 from sawmill about 50 miles away, it’s all (except the top strapping) either Larch or Douglas Fir and sourced from local forests, some from Dartmoor. About £100 of that was delivery but there’s no way I could get the long lengths home. The PT strapping was about £30 from local builders merchant for 7 lengths of 4.2m…only used about 5 in the end.

but there’s no way I could get the long lengths home. The PT strapping was about £30 from local builders merchant for 7 lengths of 4.2m…only used about 5 in the end.

Initially priced all the wood from Travis Perkins for PT kiln dried etc, that would’ve been about £650 without the 6x6 posts as most places don’t do that size, hence going to sawmill.

The post bases and beam supports were horrendous as they had to come from America, about £250 in total, which is ridiculous really, but that’s what we wanted. They are really well built (heavy!).

Also bought several different sizes of screw. All Spax from Wickes.

I bought a load of other tools and stuff to do this project, but obviously those will be reused etc.

So not cheap, although prices for timber are elevated at the moment, don’t know what it would’ve been at pre-pandemic prices.

So, including new tools, between £1500 and £2000 I reckon.

Took me about 2 and a half weeks but I didn’t work on it every day….was only meant to take about 5!!!

Timber was about £950 from sawmill about 50 miles away, it’s all (except the top strapping) either Larch or Douglas Fir and sourced from local forests, some from Dartmoor. About £100 of that was delivery

Initially priced all the wood from Travis Perkins for PT kiln dried etc, that would’ve been about £650 without the 6x6 posts as most places don’t do that size, hence going to sawmill.

The post bases and beam supports were horrendous as they had to come from America, about £250 in total, which is ridiculous really, but that’s what we wanted. They are really well built (heavy!).

Also bought several different sizes of screw. All Spax from Wickes.

I bought a load of other tools and stuff to do this project, but obviously those will be reused etc.

So not cheap, although prices for timber are elevated at the moment, don’t know what it would’ve been at pre-pandemic prices.

So, including new tools, between £1500 and £2000 I reckon.

Took me about 2 and a half weeks but I didn’t work on it every day….was only meant to take about 5!!!

That’s a really good job you’re done there and you should be very proud of yourself, the cost of the tools can be offset against the labour costs you have saved by doing it yourself and will come in for any future projects, you might even make some pocket money doing jobs for your neighbours now they can see how skilled you are

ihadablackdog

Senior member

Chippie said:That’s a really good job you’re done there and you should be very proud of yourself, the cost of the tools can be offset against the labour costs you have saved by doing it yourself and will come in for any future projects, you might even make some pocket money doing jobs for your neighbours now they can see how skilled you are

Thankyou.

Not sure about the neighbours though….guy next to me lent me his his planer/thickenesser and I broke it, so repairing or replacing it is another cost

That is an excellent job, you should be well chuffed with yourself, especially the centre mitred notch (Nitrix' solution  ). I would not have thought of that and would have had the router out.

). I would not have thought of that and would have had the router out.

Timber is far from cheap anymore; still it doesn't grow on trees I suppose

You could use wood dye on the 2x1 but you will never get it to match properly.

Timber is far from cheap anymore; still it doesn't grow on trees I suppose

You could use wood dye on the 2x1 but you will never get it to match properly.

ihadablackdog

Senior member

Pondrew said:That is an excellent job, you should be well chuffed with yourself, especially the centre mitred notch (Nitrix' solution). I would not have thought of that and would have had the router out.

Timber is far from cheap anymore; still it doesn't grow on trees I suppose

You could use wood dye on the 2x1 but you will never get it to match properly.

Thankyou.

A router is next on my list

I did contact a more local sawmill about getting the 2x1 in Larch or Douglas fir but didn’t hear back from them. If I can get some then I’ll swap it over but probably just live with it.

I’ve learnt a lot doing this and got a bit more confidence to tackle things in the future.

I did that but maybe took it a bit far. I made a coffee table having done no woodworking before, before I knew it I had made this:ihadablackdog said:I’ve learnt a lot doing this and got a bit more confidence to tackle things in the future.

Then when I had finished that I did this:

It's got a bit out of hand for me! :lol:

ihadablackdog said:A router is next on my list

If you’re planning anything major I’d suggest getting a 1/2’ router,

Something like this

https://www.screwfix.com/p/trend-t7-ek-2100w-electric-router-230v/307kg

If your only going to be doing a little moulding then a 1/4’ router would do, they aren’t as bulky or heavy as a 1/2” but obviously don’t have the guts or depth of plunge for doing deep cuts, which ever you get, as with the planer don’t be tempted to take too much out in one go

Similar threads

- Replies

- 20

- Views

- 1K