RedUn said:Ok I chose this method Vs trying to bend it which I think is a bit rubbish.

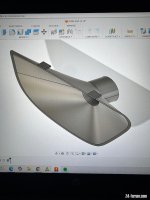

The OEM dipstick uses a fork shaped bracket which is removable which allows you to rotate the dipstick, the CSL one's come with a welded bracket.

The issue is the bracket is 180 degrees out for the Z4M if you want easy access to the dipstick.

Bracket slowly removed and painted, will install with new oem fork part and the job is a good one

Nothings ever easy eh? :lol: