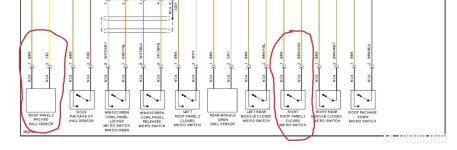

Well few weeks ago, roof fault came up. Code reader said roof module 2 hall sensor.

So today being -1.5 c temperature going home, roof bong continuous and red roof symbol and "roof not latched" all the way home.

So thinking this will be a broken wire, you can just feel the cable in the open section of the interior roof panel just alongside the head rest.

So i pushed on the cables and sure enough the red roof symbol comes and goes.

So looks like a broken wire, bit too cold at the moment to mess.

So today being -1.5 c temperature going home, roof bong continuous and red roof symbol and "roof not latched" all the way home.

So thinking this will be a broken wire, you can just feel the cable in the open section of the interior roof panel just alongside the head rest.

So i pushed on the cables and sure enough the red roof symbol comes and goes.

So looks like a broken wire, bit too cold at the moment to mess.