Uhmm, I'm not sure i you are on the right path.Stevo1987 said:After PM'ing Robbi

[...]

I connected my DVM here and teed into the wiring in the second photo where the red tape is and proved there were no breaks.I have tested the microswitch from where I cut the wire at the connector. On manually operating the mSwitch I'm getting open circuit so it looks like the microswitch is faulty.

Did you really try to measure sth. on these two wires on the 1st photo (yellow/red wire)? That is the hallsensor (HS) clipped into the hydraulic ram. It can't be simply measured by DMV, as it is an active component (a chip!) and not a switch or resistor.

On the other hand, please don't even think about tearing one of the two microswitches (MS) out of the roof, as you won't be able to mount the new ones. These 2 MS are melted into the roof!

The MS on the right has a pair of green/brown & brown wires, the one on the left has a pair of white & brown wires.

Going this way is absolutely NOT my recommendation!

You will destroy more than you can repair and there will be additional failures in the near future as you will not be able to reconstruct the original routing of the hoses and wires.

Even broken wires are held together by the fabric and will only interrupt the signal for a brief moment when the entire harness is bent.

Typically, there are short circuits or interruptions with a duration of only a few milliseconds that cause the CTM to stop the roof movement.

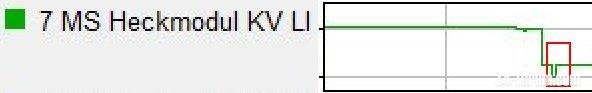

Look at the current signal (marked in red) from that very microswitch in the roof shell that has dropped to the ground for a tiny amount of time. This can't be measured with a DVM.