Hi guys

I'm currently re-assembling my entire car after a full refurb. I'm making sure to do everything by the book with correct torques etc etc.

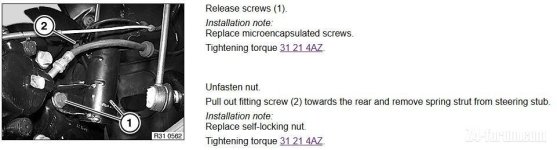

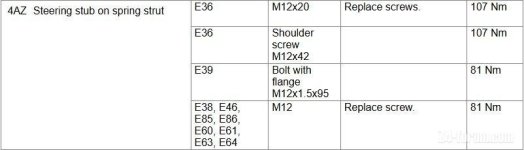

The only thing I can't find is the official torque for the 3no. M12 bolts that connect the front suspension struts to the steering knuckles.

Usually I could work it out from the steel tensile rating on the bolt heads, but these bolts have rusted heads and I can't read them.

Most guides I've found for E46 and E85 show the pinch-type strut arrangements that seem to be more common. My car is the 3 bolt arrangement, not the pinch type. I've failed to find any official data on this arrangement and bolts.

The only thing I've found is this: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://club.autodoc.co.uk/pdf-manuals/club/bmw/z4-roadster-e85/strut-mount-and-bearing/pdf/EN-how-to-change-front-strut-mount-on-bmw-z4-roadster-e85-replacement-guide.pdf&ved=2ahUKEwjs-bDvob-MAxVHT0EAHQwUGLYQFnoECCEQAQ&usg=AOvVaw1idmjjBgnsghO3vx3mI8HY

^^ but I don't know this guy and have no reason to trust him. He states 107NM. But for an M12 bolt that would mean a 10.8 tensile bolt. If mine turn out to be 8.8 tensile then I'll snap the bolts and be in trouble.

Does anyone have any experience of this?

Also does anyone know if these are red, green or blue threadlock compound? Mine are so old I can't tell.

As I said I don't want to guess/estimate anything, I want it 100% by the book.

Many thanks

I'm currently re-assembling my entire car after a full refurb. I'm making sure to do everything by the book with correct torques etc etc.

The only thing I can't find is the official torque for the 3no. M12 bolts that connect the front suspension struts to the steering knuckles.

Usually I could work it out from the steel tensile rating on the bolt heads, but these bolts have rusted heads and I can't read them.

Most guides I've found for E46 and E85 show the pinch-type strut arrangements that seem to be more common. My car is the 3 bolt arrangement, not the pinch type. I've failed to find any official data on this arrangement and bolts.

The only thing I've found is this: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://club.autodoc.co.uk/pdf-manuals/club/bmw/z4-roadster-e85/strut-mount-and-bearing/pdf/EN-how-to-change-front-strut-mount-on-bmw-z4-roadster-e85-replacement-guide.pdf&ved=2ahUKEwjs-bDvob-MAxVHT0EAHQwUGLYQFnoECCEQAQ&usg=AOvVaw1idmjjBgnsghO3vx3mI8HY

^^ but I don't know this guy and have no reason to trust him. He states 107NM. But for an M12 bolt that would mean a 10.8 tensile bolt. If mine turn out to be 8.8 tensile then I'll snap the bolts and be in trouble.

Does anyone have any experience of this?

Also does anyone know if these are red, green or blue threadlock compound? Mine are so old I can't tell.

As I said I don't want to guess/estimate anything, I want it 100% by the book.

Many thanks