Disclaimer: I'm not native English speaker, please forgive me my lingual mistakes  Thanks!

Thanks!

Hi

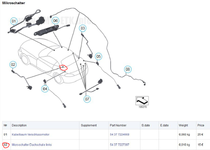

I had problem during closing roof process - the roof pack 2 (one with the glass, which open first/close last) stopped just before reach back lid and throw the fault code A68B, which means: "Microswitch, roof shell 2 closed, left"

I disconnected this switch and tested with multimeter:

- it has 0.05 Ohm when not pressed

- it has about 2.7 kOhm when pressed, so this switch is OK

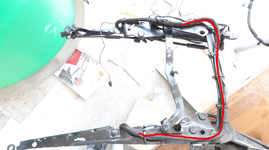

This led my suspicious to cable and bingo ! The one was broken near upper hinge mechanism (image below):

This cable is very stiff and prone to crack, when You try to bend several times. I don't know, why BMW use this poor quality cables in such demanding places (when bending is very often). The red "oval" is the place, where cables is broken.

I cut the cable and replaced with new (temporailrly) in this section to check it will work or not.

And this fix works !! But ... My plan is to order good, industrial-grade 2 or 3 or more wires cable like chainflex® CF9 (https://www.igus.co.uk/product/1013) which will able to withstand 5 000 000 bending cycles or more and replace existed ones (in both sides) in this area (images below) to prevent such problems in the future (because bending an tensions occurs in this area very often and existing wires will be broken sooner or later):

Hi

I had problem during closing roof process - the roof pack 2 (one with the glass, which open first/close last) stopped just before reach back lid and throw the fault code A68B, which means: "Microswitch, roof shell 2 closed, left"

I disconnected this switch and tested with multimeter:

- it has 0.05 Ohm when not pressed

- it has about 2.7 kOhm when pressed, so this switch is OK

This led my suspicious to cable and bingo ! The one was broken near upper hinge mechanism (image below):

This cable is very stiff and prone to crack, when You try to bend several times. I don't know, why BMW use this poor quality cables in such demanding places (when bending is very often). The red "oval" is the place, where cables is broken.

I cut the cable and replaced with new (temporailrly) in this section to check it will work or not.

And this fix works !! But ... My plan is to order good, industrial-grade 2 or 3 or more wires cable like chainflex® CF9 (https://www.igus.co.uk/product/1013) which will able to withstand 5 000 000 bending cycles or more and replace existed ones (in both sides) in this area (images below) to prevent such problems in the future (because bending an tensions occurs in this area very often and existing wires will be broken sooner or later):