A

Anonymous

Guest

I thought I would have a go at the specifics of the N20 engine in the E89. Maybe making a sticky? Comments/corrections welcome..

Planning to do an audio version for E89s next!

Enjoy..

OVERVIEW

The BMW N20 engine was announced in 2010 and was shipped in a wide range of BMW cars from 2010-2017 including 1, 2, 3 and 5 series cars as well as the Z4 (E89) and X series SUVs.

Although essentially one physical design it was offered in 4 different power levels from 154BHP to 241 BHP, primarily by changing the DME (Engine ECU) software map.

It was only ever offered as an inline 4 married to either a 6 speed manual or 8 speed ZF supplied auto (8HP45). The X-Drive versions had a different alloy sump which supported the drive shafts and transfer case, all other versions used a plastic sump.

It was a bold move by BMW as it replaced the much loved straight 6 N52 normally aspirated engine which was fitted as the 23i and 30i in the E89.

The design objectives were lower cost to manufacturer, broader fitment/commonality across the BMW product range, lower acoustic and pollution emissions and better fuel economy.

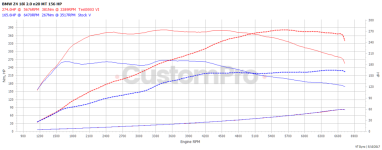

N20 28i version vs N52 30i version in the E89. The extended mathematical flat torque curve in the N20 shows a classical computer controlled management of torque and hence BHP control of many modern turbo engines.. The N52 does have some torque curve management, but not as broad and around the natural peak. This wide torque curve improves real world driveability and allows the ZF 8 Speed box to short shift to achieve good economy whilst still maintaining adequare acceleration without unnecessary down shifting.

It was replaced in turn by the 4 cylinder B48 engine, which went onto power the 20i and 30i versions of the E89’s successor the G29.

Closely related in many ways to the incoming 6 cylinder N55 engine that was never used in the E89 it had further innovations and improvements and had many further differences compared to the outgoing N52 engine.

It used an electric arc melted wire, high pressure air cylinder wall coating about 1mm thick, no re-bore possible.

3rd generation VANOS improved with an integrates solenoid valve over the N55.

The cylinder head cover (cam box) was a much cleverer design reducing some of the excess oil venting of the E89s bigger N54 engines (35i 35is).

Mitsubishi Heavy Industries provided the twin scroll turbocharger for the N20. The same version was fitted to all variants of the E89 with 17 PSI of boost possible. Twin scroll being two sets of ports each from two cylinders to give a broader range of boost performance plus better pickup.

The forged offset crank was married to offset wrist pin pistons made by FM, reducing friction and piston slap. The engine was less under square than the N52, 84mm vs 85mm with compression ratio down to 10:1 vs 10.7:1 but then boosted by turbo-charging.

Direct fuel injection into the engine was used along with new solenoid based fuel injectors to address the numerous issues of the N54 engines piezo electric injectors along with improved cylinder head cooling to reduce premature failure of the ignition coils compared to the N54 engine. There was no low pressure fuel pump.

THE N20 ENGINE IN THE E89

The N20B20 engine was fitted to the E89 in 2011 replacing the N52 engine, offered in 18i /20i /28i versions in various markets at 154 BHP / 181 BHP / 241 BHP respectively. Automatic Start / Stop was offered in manual gearbox cars from 2011 and auto box cars from 2015.

The N20 28i version compared to the N52 30i version was down on BHP 240 BHP vs 254 BHP but well up on torque over a broad range 255 ft lbs over 1250-4800 RPM vs 228 ft lbs over 2600-3000. The net effect was a much broader, stronger engine in almost all situations compared to the outgoing version.

To get around the sound and smoothness of the N52 BMW fitted an ‘Active Sound Design’ to inject suitably sexy engine noises electronically via a digital signal processor into the cars loudspeakers and also a variable noise flap on one side of the final exhaust box. This allied to twin balance shafts completed the ‘deception’.

Running gear was identical save in some markets the 28i version had 330mm front discs rather than 300mm. There were minor variations to spring rates and rear differential ratios based on engine power and manual vs auto boxes.

An interesting observation is that the 8 Speed auto box which has a much faster shift time (100mS) vs the earlier 6HP box (600mS) when married to the N20 shows its ability to stay with the engine by showing better 0-62 acceleration times than the manual box at higher power levels.

The slowest version the 18i auto did the 0-62 MPH in 8.1 seconds; the fastest stock version the 28i auto did the dash in 5.5 seconds. A 285BHP auto tuned version should be good for around 5.1 seconds.

Motoring tests suggested that the 28i variant was the sweetest handling of all E89s, combining adequate power, but less mass (60kg) and maybe less outright power than the 35i which didn’t overwhelm or ‘push’ the chassis.

The 28i auto was cited as 47.7% forward biased at 1500kg vs 49.4% for the 35is, whose mass was stated as 1610kg.

This may be explained in part by the fact that the N20 engine was much shorter and a lighter than any of the 6 cylinder variants and was placed tight against the front engine bulkhead. This resulted in much less weight in front of the front axle and reduced the moment of inertia, improving the 'turn in' ability of the car.

WIKI states "The rearward weight bias preferred by sports and racing cars results from handling effects during the transition from straight-ahead to cornering. During corner entry the front tires, in addition to generating part of the lateral force required to accelerate the car's centre of mass into the turn, also generate a torque about the car's vertical axis that starts the car rotating into the turn. However, the lateral force being generated by the rear tires is acting in the opposite torsional sense, trying to rotate the car out of the turn. For this reason, a car with "50/50" weight distribution will understeer on initial corner entry. To avoid this problem, sports and racing cars often have a more rearward weight distribution. In the case of pure racing cars, this is typically between "40/60" and "35/65". This gives the front tires an advantage in overcoming the car's moment of inertia (yaw angular inertia), thus reducing corner-entry understeer."

CHANGES DURING PRODUCTION

The engine was largely unchanged through its production run save changing from a pneumatic turbo waste gate control up to 09/13, thereafter a solenoid operated electric waste gate control.

A major revision to the cam chain tensioner /cam chain took place in 1/2015 to address premature breakup of the cam chain guide / tensioner system. At the same time a revised oil pump drive chain /tensioner was introduced.

A new turbo oil feed pipe was produced from 1/2015 which had a non-return valve in it to stop oil pooling start up smoke occurring in some engines for about 15-20 seconds after engine start.

RELIABILITY / ISSUES

Although the N20 is a reliable engine overall, some of the earlier models had timing chain issues that may be costly to fix. Simply because some engine problems are common does not mean they will indefinitely experience issues on every engine. Additionally, N20 engines are susceptible to many other issues that we will not classify as common issues, as they may only pop up on a small percentage of engines.

CAM CHAIN

The timing chain appears to be the number one fault on the N20, however, this issue is mostly prevalent on engines and vehicles produced prior to 2015. In January 2015, BMW redesigned the timing chain components, which seems to have significantly reduced the chance of failure. For certain vehicles produced prior to 2015, BMW in the US offered an extended warranty for 7 years/70,000 miles on the timing chain and components.

The new cam chain was of a more robust design and the cam chain guides were made of a different plastic much lighter, almost white in colour rather than a dirty brown colour.

The timing chain replacement can be a significant cost. In the worst scenario, a complete timing chain failure could potentially lead to engine failure. Generally, independent repair shops charge £1,500 ish for parts and repair, while the cost at a BMW dealership may be nearly double. This is a relatively tough DIY job, however, the timing chain and components cost roughly £500. Many special tools are required.

Symptoms of BMW N20 Timing Chain Failure

Loud Whining from Engine

Typically, very loud and noticeable

Significant Scoring on Chain

Too Much Slack/Play

The most common symptom is a loud, noticeable whining sound from the N20 engine. Engines may make audible, but quiet whining noises under light revs/acceleration, however, this is unlikely to indicate a timing chain issue. An overwhelmingly loud whine may suggest the timing chain is beginning to fail. Additionally, significant scoring or scratching on the timing chain may point to an underlying issue. Although, some scoring is normal due to age and wear and tear. The same may be said for slack or play in the timing chain; small amounts are normal, while significant slack or movement in the chain may suggest an issue. You may inspect the BMW N20 timing chain by peering through the oil cap.

Infrequent oil changes and/or extensive use of the auto stop start bear a correlation with these failures also.

The oil pump drive chain/tensioner and guides were revised at the same time and should be replaced at the same time. In both cases the crankshaft sprocket needs to be changed at the same time.

Failures seem to occur, if they occur in the 50k-75k miles area.

VALVE COVER

As with its larger 6-cylinder turbocharged BMW siblings, the BMW N20 uses a plastic composite valve cover (VC) and a rubber valve cover gasket (VCG). With increased mileage and age the valve cover and valve cover gaskets may become brittle and begin cracking. This is mostly due to the nature of heat cycles where the engine and components heat up and cool down constantly as you drive the car and let it rest for long periods. Once the valve cover and/or gasket develop cracks they will begin leaking oil. Typically, this begins as a minor leak and may not be noticeable until it expands, or additional cracks develop.

Symptoms of Valve Cover and/or Gasket Leaks

Visible oil leak

Burning oil smell

Smoke

Due to the tilt of the engine, this is usually noticeable just below the engine cover on the left side of the engine, when viewing the car head on. Smoke coming from the engine bay will likely become prevalent as the leaking oil may drip onto the extremely hot exhaust or turbocharger. For the same reason, you may notice a burning oil smell inside the cabin with the A/C or heat turned on, without using the air recirculation.

It is unlikely a minor leak will cause any significant issues on the N20, however, over time the leaking oil may cause premature wear on parts such as engine or transmission mounts. Fire may also be a concern as the oil typically drips onto very hot components. The N20 VC and VCG are relatively inexpensive parts at about £250 for the valve cover, gasket, ball pin, shaft seal, 4 damping elements, and 20 bolts. Repairs done at a shop may add up as it is a labour-intensive replacement.

Mileage – 6+ years, and 60,000+ miles. May be sooner, or may hold up well past 100,000 miles

OIL FILTER GASKET AND HOUSING

it is very similar to the valve cover and gasket. It is a rubber component that is subject to similar wear and tear with age, mileage, and heat cycles. The gasket may begin to crack over time, which will lead to the development of an oil leak. It is also possible the oil filter housing itself develops a crack and subsequent leak, but this is less likely than the gasket alone.

Symptoms of a leaking OFHG are like the valve however, the oil leak will be observable in the area of the oil filter housing. The gasket is only roughly £10, while the oil filter housing is over £200, including the cap, oil filter, and gaskets. The OFH/OFHG also are somewhat labour intensive, so costs may add up at independent repair shops or the BMW dealership.

N20 SPARK PLUGS AND COILS

Each time a cylinder fires, the associated ignition coil and spark plug must do their jobs completely to generate a large enough spark to generate a full burn, otherwise the engine will lose power. Eventually, due to wear and tear caused by age and mileage, the plugs and coils will no longer work to the best of their ability.

It is recommended the spark plugs are changed every 50,000-60,000 miles on stock N20 engines, while modified or tuned N20’s may require replacement as often as 20,000 to 25,000 miles. On the other hand, ignition coils should be changed every 60,000-75,000 miles on stock engines and tuned engines may burn through them as soon as 30,000 miles according to ‘experts’.

INLET PORT COKING

The direct fuel injection means there is no washing of the intake ports with fuel which does lead to oil based contamination of the inlet ports, Unlike the N54 engine, the oil control processes were substantially enhances so cleaning of the ports is not expected before 70k miles. Vibration and rough idling are the common indications of coking up.

TUNING

The N20 engines range from 154 BHP to 241 BHP in various E89 variants. All these variants run the same engine/turbo/radiators/intercooler as far as one can tell.

Because the N20 engine had a relative short production life and was not seen as tuner’s favourite toy, unlike the N54 and N55, there are much more limited availability of performance goodies especially for the low production run E89, where bodywork/bracket specific variations are needed.

The advice listed is for road use and without spending large amounts of money, those seeking 400BHP+ should seek solace with an N54 variant!

Before tuning its best to put fresh plugs and coils in as well as fresh air filters and oil!

The plastic pipe connecting the turbo to the intercooler ages and cause boost error messages such as “boost improbability’ indicating either a cracked/flexing pipe or loose clamps.

The simplest, cheapest and most effective tuning modification is to either add a ‘piggy back’ tuning box or a DME re-map. The piggbacks tend to add about 50-60 BHP to whichever version of the engine you have..so a 18i goes from 154BHP to around 210BHP and a 28i goes from 2401 BHP to 300 BHP. Different boxes have minor variations, they all tend to work by sending modified data signals from various engine sensors to the DME which changes fuel flow, boost and ignition timing to increase power. The primary advantage is that the piggy back box can be easily removed, however if you have not declared the modification to your insurance company a loss assessor will easily spot it!

The alternative is a re-map of the engine parameters inside the DME, the advantage is that any of the 18i, 20i, 28i can be boosted to almost the same levels, usually around 280 BHP-300BHP. Celtic Tuning and Evolve are well respected and proven suppliers, many others are available. Within the re-map fraternity there are two sub options: a standard tune for as it implies an otherwise standard engine, optionally a custom tune on a rolling road, usually allied to other modifications.

Moving down the equation of cost for performance, catless downpipe will not disappoint on the N20 either. The best exhaust on a turbocharged car is no exhaust after the turbo; for most of us, this likely is not practical for daily driving on public roads. The pressure drop from pre-turbo to post-turbo plays a significant role in allowing the turbocharger to spool and build boost. Removing the catalytic converter from the downpipe will increase horsepower and torque by 10-20. Additionally, a catless downpipe will allow the turbo to spool quicker, which means torque hits instantly and is a great feeling on the butt-dyno. Lastly, a catless downpipe produces a more aggressive exhaust note without sounding intrusive or droning during normal cruising.

Next if you can find one is a front mount intercooler (FMIC), this gives around 5 BHP peak power gains which are not quite as impressive as the tune or catless downpipe this mod ensures consistent performance throughout the rev range by keeping IAT’s (intake air temps) down. Cooler IAT’s mean the N20 will produce more horsepower later in the rev range and prevent the turbos from heat soaking. On a hot summer day, there are effects of heat soak on a stock intercooler; Additionally, and most importantly, cooler intake temps will reduce the risk of the N20 pre-detonating or knocking. This is extremely helpful in ensuring the longevity of your BMW N20 engine as engine knocks may be harmful to engine internals. More popular in hotter climates, not seen often in Northern Europe on this engine.

Finally some people have played around with the air intake but tuners have found negligible benefit on the N20 engines, even in upgraded versions. Putting discrete air intakes inside the engine bay is a big no no!

TUNING LIMITATIONS

Most tuners seem to stay at the 280-300 BHP limit for road cars. There have been a few cases of engines ‘letting go’ when pushed to the 320BHP-350BHP area, although some of those are associated with oil sump starvation issues on uni directional racing circuits.

Remember, N20 powered BMW’s were not designed to be all-out track cars and pushing the car too hard around long, fast corners and heavy braking may lead to oil starvation situations. Increased boost will cause the turbocharger to run hotter, and the turbo heats up a lot faster than the oil does.

Waiting till the oil temp is up to 75 centigrade before serious boost will help life as will 60 seconds spool down / cool down on the turbo if you have just been giving it ‘the beans’.

22 PSI boost is cited as a limit as is 320 lb ft of torque. Celtic Tuning backed their N20 back from 295BHP to 280BHP for these reasons.

Although the N20 unit is far better cooled relative to its intended output, thermodynamic stresses occur at a localised level and its probable that at levels much above 300BHP thermal stresses cause premature aging and subsequent failure in and around the cylinder head and pistons, leading to possible con rod failure also. For road use the possibility of holding one of these engines at full power for more than a few seconds is remote, so at the sub 300 BHP tune level engine life expectancy should be as per un tuned engine.

Planning to do an audio version for E89s next!

Enjoy..

OVERVIEW

The BMW N20 engine was announced in 2010 and was shipped in a wide range of BMW cars from 2010-2017 including 1, 2, 3 and 5 series cars as well as the Z4 (E89) and X series SUVs.

Although essentially one physical design it was offered in 4 different power levels from 154BHP to 241 BHP, primarily by changing the DME (Engine ECU) software map.

It was only ever offered as an inline 4 married to either a 6 speed manual or 8 speed ZF supplied auto (8HP45). The X-Drive versions had a different alloy sump which supported the drive shafts and transfer case, all other versions used a plastic sump.

It was a bold move by BMW as it replaced the much loved straight 6 N52 normally aspirated engine which was fitted as the 23i and 30i in the E89.

The design objectives were lower cost to manufacturer, broader fitment/commonality across the BMW product range, lower acoustic and pollution emissions and better fuel economy.

N20 28i version vs N52 30i version in the E89. The extended mathematical flat torque curve in the N20 shows a classical computer controlled management of torque and hence BHP control of many modern turbo engines.. The N52 does have some torque curve management, but not as broad and around the natural peak. This wide torque curve improves real world driveability and allows the ZF 8 Speed box to short shift to achieve good economy whilst still maintaining adequare acceleration without unnecessary down shifting.

It was replaced in turn by the 4 cylinder B48 engine, which went onto power the 20i and 30i versions of the E89’s successor the G29.

Closely related in many ways to the incoming 6 cylinder N55 engine that was never used in the E89 it had further innovations and improvements and had many further differences compared to the outgoing N52 engine.

It used an electric arc melted wire, high pressure air cylinder wall coating about 1mm thick, no re-bore possible.

3rd generation VANOS improved with an integrates solenoid valve over the N55.

The cylinder head cover (cam box) was a much cleverer design reducing some of the excess oil venting of the E89s bigger N54 engines (35i 35is).

Mitsubishi Heavy Industries provided the twin scroll turbocharger for the N20. The same version was fitted to all variants of the E89 with 17 PSI of boost possible. Twin scroll being two sets of ports each from two cylinders to give a broader range of boost performance plus better pickup.

The forged offset crank was married to offset wrist pin pistons made by FM, reducing friction and piston slap. The engine was less under square than the N52, 84mm vs 85mm with compression ratio down to 10:1 vs 10.7:1 but then boosted by turbo-charging.

Direct fuel injection into the engine was used along with new solenoid based fuel injectors to address the numerous issues of the N54 engines piezo electric injectors along with improved cylinder head cooling to reduce premature failure of the ignition coils compared to the N54 engine. There was no low pressure fuel pump.

THE N20 ENGINE IN THE E89

The N20B20 engine was fitted to the E89 in 2011 replacing the N52 engine, offered in 18i /20i /28i versions in various markets at 154 BHP / 181 BHP / 241 BHP respectively. Automatic Start / Stop was offered in manual gearbox cars from 2011 and auto box cars from 2015.

The N20 28i version compared to the N52 30i version was down on BHP 240 BHP vs 254 BHP but well up on torque over a broad range 255 ft lbs over 1250-4800 RPM vs 228 ft lbs over 2600-3000. The net effect was a much broader, stronger engine in almost all situations compared to the outgoing version.

To get around the sound and smoothness of the N52 BMW fitted an ‘Active Sound Design’ to inject suitably sexy engine noises electronically via a digital signal processor into the cars loudspeakers and also a variable noise flap on one side of the final exhaust box. This allied to twin balance shafts completed the ‘deception’.

Running gear was identical save in some markets the 28i version had 330mm front discs rather than 300mm. There were minor variations to spring rates and rear differential ratios based on engine power and manual vs auto boxes.

An interesting observation is that the 8 Speed auto box which has a much faster shift time (100mS) vs the earlier 6HP box (600mS) when married to the N20 shows its ability to stay with the engine by showing better 0-62 acceleration times than the manual box at higher power levels.

The slowest version the 18i auto did the 0-62 MPH in 8.1 seconds; the fastest stock version the 28i auto did the dash in 5.5 seconds. A 285BHP auto tuned version should be good for around 5.1 seconds.

Motoring tests suggested that the 28i variant was the sweetest handling of all E89s, combining adequate power, but less mass (60kg) and maybe less outright power than the 35i which didn’t overwhelm or ‘push’ the chassis.

The 28i auto was cited as 47.7% forward biased at 1500kg vs 49.4% for the 35is, whose mass was stated as 1610kg.

This may be explained in part by the fact that the N20 engine was much shorter and a lighter than any of the 6 cylinder variants and was placed tight against the front engine bulkhead. This resulted in much less weight in front of the front axle and reduced the moment of inertia, improving the 'turn in' ability of the car.

WIKI states "The rearward weight bias preferred by sports and racing cars results from handling effects during the transition from straight-ahead to cornering. During corner entry the front tires, in addition to generating part of the lateral force required to accelerate the car's centre of mass into the turn, also generate a torque about the car's vertical axis that starts the car rotating into the turn. However, the lateral force being generated by the rear tires is acting in the opposite torsional sense, trying to rotate the car out of the turn. For this reason, a car with "50/50" weight distribution will understeer on initial corner entry. To avoid this problem, sports and racing cars often have a more rearward weight distribution. In the case of pure racing cars, this is typically between "40/60" and "35/65". This gives the front tires an advantage in overcoming the car's moment of inertia (yaw angular inertia), thus reducing corner-entry understeer."

CHANGES DURING PRODUCTION

The engine was largely unchanged through its production run save changing from a pneumatic turbo waste gate control up to 09/13, thereafter a solenoid operated electric waste gate control.

A major revision to the cam chain tensioner /cam chain took place in 1/2015 to address premature breakup of the cam chain guide / tensioner system. At the same time a revised oil pump drive chain /tensioner was introduced.

A new turbo oil feed pipe was produced from 1/2015 which had a non-return valve in it to stop oil pooling start up smoke occurring in some engines for about 15-20 seconds after engine start.

RELIABILITY / ISSUES

Although the N20 is a reliable engine overall, some of the earlier models had timing chain issues that may be costly to fix. Simply because some engine problems are common does not mean they will indefinitely experience issues on every engine. Additionally, N20 engines are susceptible to many other issues that we will not classify as common issues, as they may only pop up on a small percentage of engines.

CAM CHAIN

The timing chain appears to be the number one fault on the N20, however, this issue is mostly prevalent on engines and vehicles produced prior to 2015. In January 2015, BMW redesigned the timing chain components, which seems to have significantly reduced the chance of failure. For certain vehicles produced prior to 2015, BMW in the US offered an extended warranty for 7 years/70,000 miles on the timing chain and components.

The new cam chain was of a more robust design and the cam chain guides were made of a different plastic much lighter, almost white in colour rather than a dirty brown colour.

The timing chain replacement can be a significant cost. In the worst scenario, a complete timing chain failure could potentially lead to engine failure. Generally, independent repair shops charge £1,500 ish for parts and repair, while the cost at a BMW dealership may be nearly double. This is a relatively tough DIY job, however, the timing chain and components cost roughly £500. Many special tools are required.

Symptoms of BMW N20 Timing Chain Failure

Loud Whining from Engine

Typically, very loud and noticeable

Significant Scoring on Chain

Too Much Slack/Play

The most common symptom is a loud, noticeable whining sound from the N20 engine. Engines may make audible, but quiet whining noises under light revs/acceleration, however, this is unlikely to indicate a timing chain issue. An overwhelmingly loud whine may suggest the timing chain is beginning to fail. Additionally, significant scoring or scratching on the timing chain may point to an underlying issue. Although, some scoring is normal due to age and wear and tear. The same may be said for slack or play in the timing chain; small amounts are normal, while significant slack or movement in the chain may suggest an issue. You may inspect the BMW N20 timing chain by peering through the oil cap.

Infrequent oil changes and/or extensive use of the auto stop start bear a correlation with these failures also.

The oil pump drive chain/tensioner and guides were revised at the same time and should be replaced at the same time. In both cases the crankshaft sprocket needs to be changed at the same time.

Failures seem to occur, if they occur in the 50k-75k miles area.

VALVE COVER

As with its larger 6-cylinder turbocharged BMW siblings, the BMW N20 uses a plastic composite valve cover (VC) and a rubber valve cover gasket (VCG). With increased mileage and age the valve cover and valve cover gaskets may become brittle and begin cracking. This is mostly due to the nature of heat cycles where the engine and components heat up and cool down constantly as you drive the car and let it rest for long periods. Once the valve cover and/or gasket develop cracks they will begin leaking oil. Typically, this begins as a minor leak and may not be noticeable until it expands, or additional cracks develop.

Symptoms of Valve Cover and/or Gasket Leaks

Visible oil leak

Burning oil smell

Smoke

Due to the tilt of the engine, this is usually noticeable just below the engine cover on the left side of the engine, when viewing the car head on. Smoke coming from the engine bay will likely become prevalent as the leaking oil may drip onto the extremely hot exhaust or turbocharger. For the same reason, you may notice a burning oil smell inside the cabin with the A/C or heat turned on, without using the air recirculation.

It is unlikely a minor leak will cause any significant issues on the N20, however, over time the leaking oil may cause premature wear on parts such as engine or transmission mounts. Fire may also be a concern as the oil typically drips onto very hot components. The N20 VC and VCG are relatively inexpensive parts at about £250 for the valve cover, gasket, ball pin, shaft seal, 4 damping elements, and 20 bolts. Repairs done at a shop may add up as it is a labour-intensive replacement.

Mileage – 6+ years, and 60,000+ miles. May be sooner, or may hold up well past 100,000 miles

OIL FILTER GASKET AND HOUSING

it is very similar to the valve cover and gasket. It is a rubber component that is subject to similar wear and tear with age, mileage, and heat cycles. The gasket may begin to crack over time, which will lead to the development of an oil leak. It is also possible the oil filter housing itself develops a crack and subsequent leak, but this is less likely than the gasket alone.

Symptoms of a leaking OFHG are like the valve however, the oil leak will be observable in the area of the oil filter housing. The gasket is only roughly £10, while the oil filter housing is over £200, including the cap, oil filter, and gaskets. The OFH/OFHG also are somewhat labour intensive, so costs may add up at independent repair shops or the BMW dealership.

N20 SPARK PLUGS AND COILS

Each time a cylinder fires, the associated ignition coil and spark plug must do their jobs completely to generate a large enough spark to generate a full burn, otherwise the engine will lose power. Eventually, due to wear and tear caused by age and mileage, the plugs and coils will no longer work to the best of their ability.

It is recommended the spark plugs are changed every 50,000-60,000 miles on stock N20 engines, while modified or tuned N20’s may require replacement as often as 20,000 to 25,000 miles. On the other hand, ignition coils should be changed every 60,000-75,000 miles on stock engines and tuned engines may burn through them as soon as 30,000 miles according to ‘experts’.

INLET PORT COKING

The direct fuel injection means there is no washing of the intake ports with fuel which does lead to oil based contamination of the inlet ports, Unlike the N54 engine, the oil control processes were substantially enhances so cleaning of the ports is not expected before 70k miles. Vibration and rough idling are the common indications of coking up.

TUNING

The N20 engines range from 154 BHP to 241 BHP in various E89 variants. All these variants run the same engine/turbo/radiators/intercooler as far as one can tell.

Because the N20 engine had a relative short production life and was not seen as tuner’s favourite toy, unlike the N54 and N55, there are much more limited availability of performance goodies especially for the low production run E89, where bodywork/bracket specific variations are needed.

The advice listed is for road use and without spending large amounts of money, those seeking 400BHP+ should seek solace with an N54 variant!

Before tuning its best to put fresh plugs and coils in as well as fresh air filters and oil!

The plastic pipe connecting the turbo to the intercooler ages and cause boost error messages such as “boost improbability’ indicating either a cracked/flexing pipe or loose clamps.

The simplest, cheapest and most effective tuning modification is to either add a ‘piggy back’ tuning box or a DME re-map. The piggbacks tend to add about 50-60 BHP to whichever version of the engine you have..so a 18i goes from 154BHP to around 210BHP and a 28i goes from 2401 BHP to 300 BHP. Different boxes have minor variations, they all tend to work by sending modified data signals from various engine sensors to the DME which changes fuel flow, boost and ignition timing to increase power. The primary advantage is that the piggy back box can be easily removed, however if you have not declared the modification to your insurance company a loss assessor will easily spot it!

The alternative is a re-map of the engine parameters inside the DME, the advantage is that any of the 18i, 20i, 28i can be boosted to almost the same levels, usually around 280 BHP-300BHP. Celtic Tuning and Evolve are well respected and proven suppliers, many others are available. Within the re-map fraternity there are two sub options: a standard tune for as it implies an otherwise standard engine, optionally a custom tune on a rolling road, usually allied to other modifications.

Moving down the equation of cost for performance, catless downpipe will not disappoint on the N20 either. The best exhaust on a turbocharged car is no exhaust after the turbo; for most of us, this likely is not practical for daily driving on public roads. The pressure drop from pre-turbo to post-turbo plays a significant role in allowing the turbocharger to spool and build boost. Removing the catalytic converter from the downpipe will increase horsepower and torque by 10-20. Additionally, a catless downpipe will allow the turbo to spool quicker, which means torque hits instantly and is a great feeling on the butt-dyno. Lastly, a catless downpipe produces a more aggressive exhaust note without sounding intrusive or droning during normal cruising.

Next if you can find one is a front mount intercooler (FMIC), this gives around 5 BHP peak power gains which are not quite as impressive as the tune or catless downpipe this mod ensures consistent performance throughout the rev range by keeping IAT’s (intake air temps) down. Cooler IAT’s mean the N20 will produce more horsepower later in the rev range and prevent the turbos from heat soaking. On a hot summer day, there are effects of heat soak on a stock intercooler; Additionally, and most importantly, cooler intake temps will reduce the risk of the N20 pre-detonating or knocking. This is extremely helpful in ensuring the longevity of your BMW N20 engine as engine knocks may be harmful to engine internals. More popular in hotter climates, not seen often in Northern Europe on this engine.

Finally some people have played around with the air intake but tuners have found negligible benefit on the N20 engines, even in upgraded versions. Putting discrete air intakes inside the engine bay is a big no no!

TUNING LIMITATIONS

Most tuners seem to stay at the 280-300 BHP limit for road cars. There have been a few cases of engines ‘letting go’ when pushed to the 320BHP-350BHP area, although some of those are associated with oil sump starvation issues on uni directional racing circuits.

Remember, N20 powered BMW’s were not designed to be all-out track cars and pushing the car too hard around long, fast corners and heavy braking may lead to oil starvation situations. Increased boost will cause the turbocharger to run hotter, and the turbo heats up a lot faster than the oil does.

Waiting till the oil temp is up to 75 centigrade before serious boost will help life as will 60 seconds spool down / cool down on the turbo if you have just been giving it ‘the beans’.

22 PSI boost is cited as a limit as is 320 lb ft of torque. Celtic Tuning backed their N20 back from 295BHP to 280BHP for these reasons.

Although the N20 unit is far better cooled relative to its intended output, thermodynamic stresses occur at a localised level and its probable that at levels much above 300BHP thermal stresses cause premature aging and subsequent failure in and around the cylinder head and pistons, leading to possible con rod failure also. For road use the possibility of holding one of these engines at full power for more than a few seconds is remote, so at the sub 300 BHP tune level engine life expectancy should be as per un tuned engine.