On my e86 Z4M the horns dont work. When pressing the steering wheel I can hear a click from behind the glove box which makes me think the signal may be getting at least as far as the relay.

As a start to my Z4M ownership journey I have now bought some low profile ramps, a low profile jack, some jack stands, wheel chocks and some jack point rubber pads (I have seen mangled jack points before).

As [ref]enuff_zed[/ref] suggests in another thread the first thing I will try is replacing the horns as [ref]umfaan[/ref] happened to be selling a pair on here the other day.

I plan to follow the guide at https://www.youtube.com/watch?v=sELrm_yYQCg to lift the car. Then remove one front wheel, remove the arch liner and connect a replacement horn into the connector to see if that works. If it works I will put the arch liner and wheel back and then try the other side.

I would be grateful for any advice, warnings, tips about this process please.

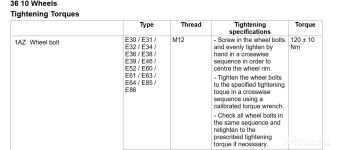

As a starter, is there a specific torque that should be applied when attaching wheel nuts to a wheel hub when reinstalling the wheel?

As a start to my Z4M ownership journey I have now bought some low profile ramps, a low profile jack, some jack stands, wheel chocks and some jack point rubber pads (I have seen mangled jack points before).

As [ref]enuff_zed[/ref] suggests in another thread the first thing I will try is replacing the horns as [ref]umfaan[/ref] happened to be selling a pair on here the other day.

I plan to follow the guide at https://www.youtube.com/watch?v=sELrm_yYQCg to lift the car. Then remove one front wheel, remove the arch liner and connect a replacement horn into the connector to see if that works. If it works I will put the arch liner and wheel back and then try the other side.

I would be grateful for any advice, warnings, tips about this process please.

As a starter, is there a specific torque that should be applied when attaching wheel nuts to a wheel hub when reinstalling the wheel?