smorris_12

Active member

From the day I bought my Z I was scraping the living hell out of the front splitter. I was used to the idea that it's a low 2-seater but it was ridiculous. Almost any shaped speed hump would grind. I did some googling and found that 2.5si's seemed to be prone to sitting low. I came across the BMW figures for ride height (and then lost them again - repeatedly. I could never seem to locate them reliably when I actually had the time to do some reading. Grrr) and eventually broke out the tape measure and got outside.

With 18s, BMW state 602mm rim to arch, +/-10mm when loaded up. Mine were 585 (driver's) & 590 (passenger). Somewhat low. The springs weren't broken but the top mounts weren't in the best of health with a couple of tears in them. I bought some new top mounts and tried to work out if they were responsible for any of the height loss while being too lazy to remove the strut. I came up with a figure of 5/6mm.

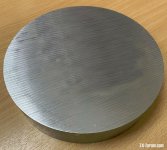

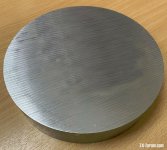

From this, while not in a drunken stupour, I decided, yes, I will, I shall raise the Titanic!..... No, wait, I mean suspension strut. By about 12mm. Or half an inch as Farage will have it. To do this I needed a disc of metal between top mount and chassis leg to keep the two apart. So I went and bought some lovely, tasty aluminium (best 150mm diameter x 17mm) from eBay and proceeded to run it through with a hole cutter in my pillar drill and tidied it up in the lathe:

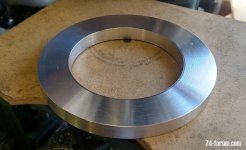

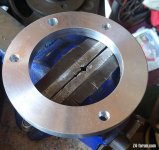

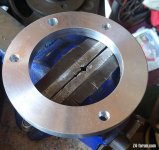

I marked off the three mounting holes (8mm) and the alignment hole (10mm) and then drilled them through. The new top mounts had their press studs removed forcibly by hammer so I could put longer plain bolts through the whole assembly while the mounting holes are partly threaded so that I could attach them to the top mount to make one assembly that would go into place nicely. Trying to manoeuvre multiple loose bits inside the strut tower seemed like it would lead to insanity.

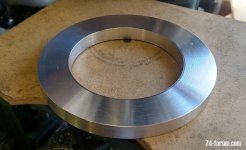

The ring was put in the lathe to reduce the outer diameter to match the top mount and thin it down from 17mm to 12 and bolted to the top mount with 10.9 set screws (which I bought too long because stoopidity.)

I pulled the struts out and removed the old top mounts using a home brew spring compressor that, while it looks like it's made out of angle iron and random bits of scrap by Dr Frankenstein after a hard night in the tap room of the Lightning Rod and Hunchback, is infinitely superior to those

damned

damned  spring compressors they sell in Halfords.

spring compressors they sell in Halfords.

I put it all back together and I got 600mm & 605mm, exactly 15mm up on where I started. In hindsight I wish I'd made them a bit thicker but I had visions of it looking like it was on stilts if it did turn out that the top mounts were much flatter. As you can see, they'd lost about 5mm.

What does this translate to? Before:

After:

It's hard to see the difference as the photos are crap as I'm up against the fence for these; the drivers side pics all ended up in shadow and out of focus. Did I mention my appalling phone camera? But the wheel now looks more centred in the arch and, best of all, I've not scraped a single thing in the month since.

With 18s, BMW state 602mm rim to arch, +/-10mm when loaded up. Mine were 585 (driver's) & 590 (passenger). Somewhat low. The springs weren't broken but the top mounts weren't in the best of health with a couple of tears in them. I bought some new top mounts and tried to work out if they were responsible for any of the height loss while being too lazy to remove the strut. I came up with a figure of 5/6mm.

From this, while not in a drunken stupour, I decided, yes, I will, I shall raise the Titanic!..... No, wait, I mean suspension strut. By about 12mm. Or half an inch as Farage will have it. To do this I needed a disc of metal between top mount and chassis leg to keep the two apart. So I went and bought some lovely, tasty aluminium (best 150mm diameter x 17mm) from eBay and proceeded to run it through with a hole cutter in my pillar drill and tidied it up in the lathe:

I marked off the three mounting holes (8mm) and the alignment hole (10mm) and then drilled them through. The new top mounts had their press studs removed forcibly by hammer so I could put longer plain bolts through the whole assembly while the mounting holes are partly threaded so that I could attach them to the top mount to make one assembly that would go into place nicely. Trying to manoeuvre multiple loose bits inside the strut tower seemed like it would lead to insanity.

The ring was put in the lathe to reduce the outer diameter to match the top mount and thin it down from 17mm to 12 and bolted to the top mount with 10.9 set screws (which I bought too long because stoopidity.)

I pulled the struts out and removed the old top mounts using a home brew spring compressor that, while it looks like it's made out of angle iron and random bits of scrap by Dr Frankenstein after a hard night in the tap room of the Lightning Rod and Hunchback, is infinitely superior to those

I put it all back together and I got 600mm & 605mm, exactly 15mm up on where I started. In hindsight I wish I'd made them a bit thicker but I had visions of it looking like it was on stilts if it did turn out that the top mounts were much flatter. As you can see, they'd lost about 5mm.

What does this translate to? Before:

After:

It's hard to see the difference as the photos are crap as I'm up against the fence for these; the drivers side pics all ended up in shadow and out of focus. Did I mention my appalling phone camera? But the wheel now looks more centred in the arch and, best of all, I've not scraped a single thing in the month since.