Hi all

Symptoms- very laboured starting for a while- as I drive the car only once a week I presumed the battery was on the way out- wrong!

Once or twice I was greeted with a click and no turnover. When it did this at work I started to look at the starter motor- especially as it went from click to start after tapping the motor with a BFH.

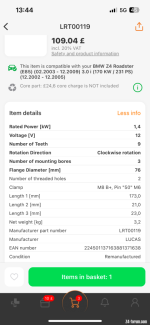

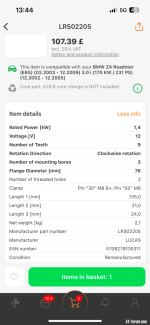

Replacement bought using myriad of discount codes from EuroCrapParts- decent price of under £60 when I take the old one back for reconditioning.

Onto the car:

Disconnect battery.

Had a good feel around the areas- decided against taking the airbox, intake boot and intake manifold off. Note a lot of guides suggest this needs to be done- mine being a 2.2 I DIDNT need to do this with adequate space to work.

Here is the business end of the starter, tucked under the intake manifold. Have a look and move/unclip any hoses that might get in the way. I moved very little.

First task- undo/loosen the bolts holding the starter motor to the bell housing- I used E12 Torx spanner to break the grip then undid with a 10mm normal socket once moving. Once they were loose I then focussed on the electrical connections. From this photo you can see the torx spanner on one and arrowed is the other. Easy to get to from the top of the engine. Note the rear of the car is to the RIGHT.

The electrical connections- 13mm BIG bolt held on 2 heavy duty electrical wires, mine were red. Once off and safely stowed I undid the 10mm low volt wire. Likewise I safely stowed this away out of the way.

Time to get the motor off- it separated with a bit of wiggling, moving toward the front of the car. With some manoeuvring around hoses out it came!

The new one ready to go in- now this was about 10mm longer in the body than the old one but there was plenty of clearance. I tweaked up the bolts to hold it in place, then connected and tightened (NOT overtight on the 10mm low voltage that felt a bit fragile). Put all the hoses and clips back on, reconnected the battery and done!

Any questions please drop me a line- 45mins start to finish on a cold December day- minimal tools and maximum satisfaction!

Cheers

Stuart

Symptoms- very laboured starting for a while- as I drive the car only once a week I presumed the battery was on the way out- wrong!

Once or twice I was greeted with a click and no turnover. When it did this at work I started to look at the starter motor- especially as it went from click to start after tapping the motor with a BFH.

Replacement bought using myriad of discount codes from EuroCrapParts- decent price of under £60 when I take the old one back for reconditioning.

Onto the car:

Disconnect battery.

Had a good feel around the areas- decided against taking the airbox, intake boot and intake manifold off. Note a lot of guides suggest this needs to be done- mine being a 2.2 I DIDNT need to do this with adequate space to work.

Here is the business end of the starter, tucked under the intake manifold. Have a look and move/unclip any hoses that might get in the way. I moved very little.

First task- undo/loosen the bolts holding the starter motor to the bell housing- I used E12 Torx spanner to break the grip then undid with a 10mm normal socket once moving. Once they were loose I then focussed on the electrical connections. From this photo you can see the torx spanner on one and arrowed is the other. Easy to get to from the top of the engine. Note the rear of the car is to the RIGHT.

The electrical connections- 13mm BIG bolt held on 2 heavy duty electrical wires, mine were red. Once off and safely stowed I undid the 10mm low volt wire. Likewise I safely stowed this away out of the way.

Time to get the motor off- it separated with a bit of wiggling, moving toward the front of the car. With some manoeuvring around hoses out it came!

The new one ready to go in- now this was about 10mm longer in the body than the old one but there was plenty of clearance. I tweaked up the bolts to hold it in place, then connected and tightened (NOT overtight on the 10mm low voltage that felt a bit fragile). Put all the hoses and clips back on, reconnected the battery and done!

Any questions please drop me a line- 45mins start to finish on a cold December day- minimal tools and maximum satisfaction!

Cheers

Stuart