Just had a PM asking me how to change the ATF, I know I did my own recently and posted a couple of pics, but after I'd typed all this out I thought others may find it useful, so here goes. No pics, but pretty self-explanatory.

Tools required;

6mm and (short) 8mm hex

Low range torque wrench

Buckets x 2

A BIG fluid syringe to fill the box

Diagnostic access to the gearbox ECU

Throughout the procedure, the car has to be kept level BTW, so this can't be done with the front on ramps.

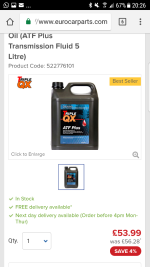

I use fully synthetic from Euro, don't have the part No to hand though, I pay about £28 for 5L. I also change the sump gasket and filter at the same time (£20)

The trick is getting as much as poss of the old fluid out, as the torque converter holds about 4L on it's own and you can't drain it without removing it.

The way I do it, is to get it up to temp, and in the air. I then remove the drain on the sump 6mm hex, this will get you about 3L. Leave that to drain.

Then I remove both hoses from the transmission cooler at the bottom of the rad, and point them into a bucket. The trick with these, is to CAREFULLY press in the plastic retaining ring at the end, this then allows the hose to slide off. Then I start the engine and let it idle, whilst moving the selector through each position. This won't damage the box in any way, but it WILL get another 3L of old fluid out, and at the same time, more will come from the sump. This way, you will get 8-9L of old fluid out.

Put the hoses back on, and then I remove the sump and change the filter, being careful not to break the plastic tabs on the new one when refitting. Remove and clean the magnets on the sump and replace. New gasket on and refit - Torque wrench and even sequence is important, so as not to distort pan and cause a leak.

Remove the filling plug, this is an 8mm hex, but clearance is very tight, I have a 3/8" socket that I cut and ground so the actual hex is only 6mm long, this fits perfectly and allows it to be used with either a breaker bar or a torque wrench.

Then fill the box until fluid starts to dribble out of the filler, this is awkward as access is tight, but I use a BIG fluid syringe which does the job well.

Once it dribbles, screw the filler plug back in and nip up lightly. Start engine and run box through all positions before stopping and fill up some more until it dribbles. Replace plug.

Now is the crucial bit, the fluid level can only accurately be checked with the engine running, and the fluid at a temp of between 40 and 50 degrees C, as the fluid expands quite a bit.

So you have to connect the diagnostic and once 40 degrees is reached, put the selector into each position and back to park, and with the engine running, remove the filler plug. IF fluid dribbles out, the level is correct, if not, top it up until it dribbles, replace plug, run through selector positions and check again. BUT this has to be done before the temp reaches 50 degrees, otherwise the fluid expands, dribbles out and you end up with a low fluid level, which can cause slipping of the box.

Hope that makes sense!

Mike

Tools required;

6mm and (short) 8mm hex

Low range torque wrench

Buckets x 2

A BIG fluid syringe to fill the box

Diagnostic access to the gearbox ECU

Throughout the procedure, the car has to be kept level BTW, so this can't be done with the front on ramps.

I use fully synthetic from Euro, don't have the part No to hand though, I pay about £28 for 5L. I also change the sump gasket and filter at the same time (£20)

The trick is getting as much as poss of the old fluid out, as the torque converter holds about 4L on it's own and you can't drain it without removing it.

The way I do it, is to get it up to temp, and in the air. I then remove the drain on the sump 6mm hex, this will get you about 3L. Leave that to drain.

Then I remove both hoses from the transmission cooler at the bottom of the rad, and point them into a bucket. The trick with these, is to CAREFULLY press in the plastic retaining ring at the end, this then allows the hose to slide off. Then I start the engine and let it idle, whilst moving the selector through each position. This won't damage the box in any way, but it WILL get another 3L of old fluid out, and at the same time, more will come from the sump. This way, you will get 8-9L of old fluid out.

Put the hoses back on, and then I remove the sump and change the filter, being careful not to break the plastic tabs on the new one when refitting. Remove and clean the magnets on the sump and replace. New gasket on and refit - Torque wrench and even sequence is important, so as not to distort pan and cause a leak.

Remove the filling plug, this is an 8mm hex, but clearance is very tight, I have a 3/8" socket that I cut and ground so the actual hex is only 6mm long, this fits perfectly and allows it to be used with either a breaker bar or a torque wrench.

Then fill the box until fluid starts to dribble out of the filler, this is awkward as access is tight, but I use a BIG fluid syringe which does the job well.

Once it dribbles, screw the filler plug back in and nip up lightly. Start engine and run box through all positions before stopping and fill up some more until it dribbles. Replace plug.

Now is the crucial bit, the fluid level can only accurately be checked with the engine running, and the fluid at a temp of between 40 and 50 degrees C, as the fluid expands quite a bit.

So you have to connect the diagnostic and once 40 degrees is reached, put the selector into each position and back to park, and with the engine running, remove the filler plug. IF fluid dribbles out, the level is correct, if not, top it up until it dribbles, replace plug, run through selector positions and check again. BUT this has to be done before the temp reaches 50 degrees, otherwise the fluid expands, dribbles out and you end up with a low fluid level, which can cause slipping of the box.

Hope that makes sense!

Mike