Seems to be a lot of threads with mixed information in the forum archives.

How best do you raise an E85/86 so you can remove the front wheel, and where is the best place for a jack stand if you’re in the way with your jack?

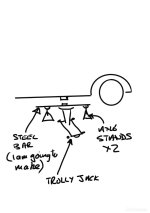

I have a low profile trolley jack and plenty of axle stands.

How best do you raise an E85/86 so you can remove the front wheel, and where is the best place for a jack stand if you’re in the way with your jack?

I have a low profile trolley jack and plenty of axle stands.