Well it’s been a few days since I bought any bits for the latest Yellow Peril.

It’s dangerous to wander into the forums and then ideas start to happen.

I’ve ended up buying a pair of TTE500s for the 35is.

https://tteglobal.com/bmw/1-series/e82e88e87/135i/71/tte500-n54-upgrade-turbochargers

The N54’s boost is implemented with the help of two Mitsubishi TD03-10TK3 turbo chargers which operate in parallel. Every turbocharger is in charge of its 3 cylinders from the block. The N54 engine has a boost pressure of 0.55 bar/8 PSI.

You can raise the boost pressure up to about 16 to 19 psi relatively easily which is what I’ve done using the stock MHD flash off the shelf maps.

The onboard boost sensor itself limits max boost to around 20 psi but by then the turbos are running out of puff and you are badly into the laws of diminishing returns.

The TTE500 is a German production of what’s called a hybrid turbo. That is it’s a stock OE turbo which then is used as a carcass to be used with better designed / engineered impellers and exhaust turbines plus other parts.

The advantages are that it allows a relatively bolt on capability with little physical hardware changes.

This is relevant especially for RHD cars as the steering linkages go through the same area as the turbos and their plumbing.

Through a combo of better aerodynamics, better engineering the same physical carcass can be made be made to flow more air AND generate more boost.

I had already gone down this route with my E89 20i, this time using a MHI produced uprated version of the OE unit.

The N54 is well documented as one very tough, very scalable engine…people have taken it well beyond 1,000 crank BHP…

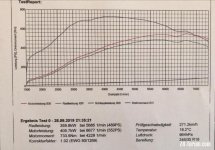

I chose the TTE500 as although it’s designed to do a mere 500 wheel not crank BHP it’s torque curve starts with and climbs alongside the stock torque curve and then just keeps climbing.

The bigger twin turbos do generate more power BUT the torque comes in later.

For street use I prioritised street oriented torque over max possible BHP.

In addition with the exception of an uprated boost sensor and some better inlet plumbing the rest of the hardware can remain stockish..

Part of criteria is to be able run a decent filtration system which precludes the DCI (dual cone intakes)..so at this stage it will be into see how rest that really is.

It appears that a lot of plumbing issues on other N54 installations were not replicated on the E89.

Boost is implemented with the help of two Mitsubishi TD03-10TK3 turbo chargers which operate in parallel. Every turbocharger is in charge of its 3 cylinders from the block. The N54 engine has a boost pressure of 0.55 bar/8 PSI.

It’s dangerous to wander into the forums and then ideas start to happen.

I’ve ended up buying a pair of TTE500s for the 35is.

https://tteglobal.com/bmw/1-series/e82e88e87/135i/71/tte500-n54-upgrade-turbochargers

The N54’s boost is implemented with the help of two Mitsubishi TD03-10TK3 turbo chargers which operate in parallel. Every turbocharger is in charge of its 3 cylinders from the block. The N54 engine has a boost pressure of 0.55 bar/8 PSI.

You can raise the boost pressure up to about 16 to 19 psi relatively easily which is what I’ve done using the stock MHD flash off the shelf maps.

The onboard boost sensor itself limits max boost to around 20 psi but by then the turbos are running out of puff and you are badly into the laws of diminishing returns.

The TTE500 is a German production of what’s called a hybrid turbo. That is it’s a stock OE turbo which then is used as a carcass to be used with better designed / engineered impellers and exhaust turbines plus other parts.

The advantages are that it allows a relatively bolt on capability with little physical hardware changes.

This is relevant especially for RHD cars as the steering linkages go through the same area as the turbos and their plumbing.

Through a combo of better aerodynamics, better engineering the same physical carcass can be made be made to flow more air AND generate more boost.

I had already gone down this route with my E89 20i, this time using a MHI produced uprated version of the OE unit.

The N54 is well documented as one very tough, very scalable engine…people have taken it well beyond 1,000 crank BHP…

I chose the TTE500 as although it’s designed to do a mere 500 wheel not crank BHP it’s torque curve starts with and climbs alongside the stock torque curve and then just keeps climbing.

The bigger twin turbos do generate more power BUT the torque comes in later.

For street use I prioritised street oriented torque over max possible BHP.

In addition with the exception of an uprated boost sensor and some better inlet plumbing the rest of the hardware can remain stockish..

Part of criteria is to be able run a decent filtration system which precludes the DCI (dual cone intakes)..so at this stage it will be into see how rest that really is.

It appears that a lot of plumbing issues on other N54 installations were not replicated on the E89.

Boost is implemented with the help of two Mitsubishi TD03-10TK3 turbo chargers which operate in parallel. Every turbocharger is in charge of its 3 cylinders from the block. The N54 engine has a boost pressure of 0.55 bar/8 PSI.