Hi all, I've been trying to do a cylinder compression test recently on my 2.0i, partially to check the health of the engine and also just to eliminate some possible causes of slightly uneven idle. The car's generally running well.

When I've done this test, both with the engine hot and when cold, I'm getting very high readings. After cranking four times, I got the following PSI: 215, 200, 195, 200. I've tried cranking a little longer, but once up to 225PSI, I got concerned about blowing something.

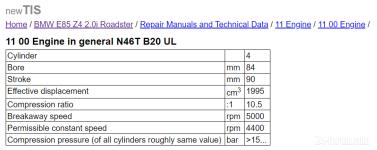

As far as I can tell, normal should be about 150PSI. From what I've read, high readings seem to either indicate a problem with the gauge (it's new from US Pro) or possibly carbon build up. Any thoughts? Is there a simple way of testing the gauge?

Thanks.

When I've done this test, both with the engine hot and when cold, I'm getting very high readings. After cranking four times, I got the following PSI: 215, 200, 195, 200. I've tried cranking a little longer, but once up to 225PSI, I got concerned about blowing something.

As far as I can tell, normal should be about 150PSI. From what I've read, high readings seem to either indicate a problem with the gauge (it's new from US Pro) or possibly carbon build up. Any thoughts? Is there a simple way of testing the gauge?

Thanks.