You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wanted-e85 3.0i clutch and flywheel

- Thread starter z4all

- Start date

Hi GuidoK (sorry for thread hijack OP but you may find it useful),

I am about to undertake a clutch and DMF change myself as the biting point is very high and I have a bit of rattle on the DMF. I’ve changed clutches before on old cars (Ford Carpis and Cortinas etc) but never on such a modern car and nothing with a DMF. I have hired a four post lift for the day and lots of tools come with it from Ramp It Up such as air tools etc. I will also take some of my specialist tools just in case.

I have looked in ECP and found a clutch kit and DMF for just under 400 with discounts applied etc. see below

Cluctch kit;

http://www.eurocarparts.com/ecp/c/BMW_Z4+Coupe_3.0_2006/p/car-parts/clutch-and-associated-parts/car-transmission/clutch-kit/?641110890&1&1b35bf37247ed0d5921565a5425cf381232775de&000069

DMF;

http://www.eurocarparts.com/ecp/c/BMW_Z4+Coupe_3.0_2006/p/car-parts/clutch-and-associated-parts/car-transmission/flywheel/?336111240&1&63af2b67e382bd4f36cb9d3b7c2dbfbd003d1dd5&000134

You seem like you have a lot of experience with this area so I wanted to pick your brains. I know I will need to remove my exhaust and deal with the rusted bots (already dreading this). Then the heat shield and prop. I will mark the prop on the diff before removal for balancing purposes. I will then remove the linkages, supports and bell housing bolts etc to release the box. The garage also have a transmission jack I can use which will be useful.

My question is, will I need any special tools to install the DMF and clutch as they will all be brand new? Will I need a locator tool or can I just bolt on as I go according to TIS (I have bought a copy of this for torque specifications).

As it seems a solid flywheel is about the same price is this a good option or would you stick to factory spec? Also while the box is out it will be getting a full fluid flush and the CDV delete. The car in question by the way is a 2006 coupe 3.0si manual.

I am about to undertake a clutch and DMF change myself as the biting point is very high and I have a bit of rattle on the DMF. I’ve changed clutches before on old cars (Ford Carpis and Cortinas etc) but never on such a modern car and nothing with a DMF. I have hired a four post lift for the day and lots of tools come with it from Ramp It Up such as air tools etc. I will also take some of my specialist tools just in case.

I have looked in ECP and found a clutch kit and DMF for just under 400 with discounts applied etc. see below

Cluctch kit;

http://www.eurocarparts.com/ecp/c/BMW_Z4+Coupe_3.0_2006/p/car-parts/clutch-and-associated-parts/car-transmission/clutch-kit/?641110890&1&1b35bf37247ed0d5921565a5425cf381232775de&000069

DMF;

http://www.eurocarparts.com/ecp/c/BMW_Z4+Coupe_3.0_2006/p/car-parts/clutch-and-associated-parts/car-transmission/flywheel/?336111240&1&63af2b67e382bd4f36cb9d3b7c2dbfbd003d1dd5&000134

You seem like you have a lot of experience with this area so I wanted to pick your brains. I know I will need to remove my exhaust and deal with the rusted bots (already dreading this). Then the heat shield and prop. I will mark the prop on the diff before removal for balancing purposes. I will then remove the linkages, supports and bell housing bolts etc to release the box. The garage also have a transmission jack I can use which will be useful.

My question is, will I need any special tools to install the DMF and clutch as they will all be brand new? Will I need a locator tool or can I just bolt on as I go according to TIS (I have bought a copy of this for torque specifications).

As it seems a solid flywheel is about the same price is this a good option or would you stick to factory spec? Also while the box is out it will be getting a full fluid flush and the CDV delete. The car in question by the way is a 2006 coupe 3.0si manual.

I'm not that experienced... I only did 1 clutch job on my z4

You need a locator tool for the cluch plate. otherwise it wont sit centered and you wont be able to get the priseshaft from the gearbox in it.

When you buy a new pressure plate, there sits a holding piece in the middle to lock the self adjusting mechanism in place.

Because of that holding piece, you cant use a regular locator tool for the clutch plate, as a regular locator tool sticks out.

BMW soved that by making a very short locator tool that you can pull out with a bolt (it has a threaded insert).

If you have a plastic locator maybe you can saw that off to the correct length and afterward pull that out with pliers, or it may also accept a bolt.

I made a locator tool myself (by sticking a small socket in a larger socket), but I didnt have that problem with the holding piece in the center of the pressure plate as my new clutch was a conventional clutch (not self adjusting)

To get the holding piece out of the pressure plate, you need a 14mm hex (thats not in every toolkit).

Also to get the dmf off you need that holding jig that grabs into the starter teeth (you cant hold it by hand, the bolts are pretty tight), and I think the dmf bolts are torx T60. That's also not in every toolkit.

I cant say much about the valeo solid flywheel conversion. I suspect you loose some comfort/premium feel (every car today has a dmf), and maybe the clutch is heavier than stock. I would be able to live with that as my car is completely modified (much more nvh overall) and I would enjoy the perfomance benefits (I think a normal clutch has a more defined bite point), but if it's your daily and use it for it's cruising abilities, I'd go for stock.

Does that flywheel come with it's centerbearing? (I think so, but it is something to check before you get the gearbox off)

If you're going to do this with not your own tools, I suggest you do it with an assistent.

Also to get the exhaust off etc. The first time you do that it's an akward job as it is long, heavy and out of balance. If you've done that 50 times, you get a real feel for it

I also suggest you keep an oxygen torch handy for those exhaust bolts.

I suggest you replace the stock nuts with copper plated nuts, I think those are better. And replace the gaskets obviously.

What you can also do is if you replace the M10 studs in the manifold (when you drill them out or heat them up and hammer them out) is to replace them with an M8 bolt (maybe allenhead for better access) and m8 copper nut (and washers on both sides). That way in the future if everything is rusted/seized again you can angle grind the nut or bolthead off and everything drops out. That's what I did on my current setup (but I have a wider exhaust diameter with different flanges, so access to boltheads is even worse)

You need a locator tool for the cluch plate. otherwise it wont sit centered and you wont be able to get the priseshaft from the gearbox in it.

When you buy a new pressure plate, there sits a holding piece in the middle to lock the self adjusting mechanism in place.

Because of that holding piece, you cant use a regular locator tool for the clutch plate, as a regular locator tool sticks out.

BMW soved that by making a very short locator tool that you can pull out with a bolt (it has a threaded insert).

If you have a plastic locator maybe you can saw that off to the correct length and afterward pull that out with pliers, or it may also accept a bolt.

I made a locator tool myself (by sticking a small socket in a larger socket), but I didnt have that problem with the holding piece in the center of the pressure plate as my new clutch was a conventional clutch (not self adjusting)

To get the holding piece out of the pressure plate, you need a 14mm hex (thats not in every toolkit).

Also to get the dmf off you need that holding jig that grabs into the starter teeth (you cant hold it by hand, the bolts are pretty tight), and I think the dmf bolts are torx T60. That's also not in every toolkit.

I cant say much about the valeo solid flywheel conversion. I suspect you loose some comfort/premium feel (every car today has a dmf), and maybe the clutch is heavier than stock. I would be able to live with that as my car is completely modified (much more nvh overall) and I would enjoy the perfomance benefits (I think a normal clutch has a more defined bite point), but if it's your daily and use it for it's cruising abilities, I'd go for stock.

Does that flywheel come with it's centerbearing? (I think so, but it is something to check before you get the gearbox off)

If you're going to do this with not your own tools, I suggest you do it with an assistent.

Also to get the exhaust off etc. The first time you do that it's an akward job as it is long, heavy and out of balance. If you've done that 50 times, you get a real feel for it

I also suggest you keep an oxygen torch handy for those exhaust bolts.

I suggest you replace the stock nuts with copper plated nuts, I think those are better. And replace the gaskets obviously.

What you can also do is if you replace the M10 studs in the manifold (when you drill them out or heat them up and hammer them out) is to replace them with an M8 bolt (maybe allenhead for better access) and m8 copper nut (and washers on both sides). That way in the future if everything is rusted/seized again you can angle grind the nut or bolthead off and everything drops out. That's what I did on my current setup (but I have a wider exhaust diameter with different flanges, so access to boltheads is even worse)

Well luckily for me my exhaust bolts have disappeared on their own. My flage support fell off the other day so the bolts must be non existent. Wont have a torch available to me but will have a good drill and drill bits plus a grinder if need be.

I knew of the clutch locator tool and was just going to find a tube or something that fits. Did not know about this flywheel jig? What, how and where??

Also the holding piece in the pressure plate I presume is just to keep it in position for transport purposes and you simply remove the bolt?

I think I'm going to stick with the oem DMF as otherwise it's possible I'll prematurely wear out other parts of the drive train.

Also, by DMF centre bearing, do you mean the clutch release bearing that comes with the clutch kit or should this come with the dmf?

Sorry for the Spanish inquisition!!

I knew of the clutch locator tool and was just going to find a tube or something that fits. Did not know about this flywheel jig? What, how and where??

Also the holding piece in the pressure plate I presume is just to keep it in position for transport purposes and you simply remove the bolt?

I think I'm going to stick with the oem DMF as otherwise it's possible I'll prematurely wear out other parts of the drive train.

Also, by DMF centre bearing, do you mean the clutch release bearing that comes with the clutch kit or should this come with the dmf?

Sorry for the Spanish inquisition!!

No the holding piece inside the pressure plate is to lock the self adjusting mechanism. So that can only be removed if/when you installed the new clutch plate and the pressure plate is already on top.

If you dont get a new pressure plate and new clutch plate (for example just replace clutch plate and keep the old pressure plate) you need a special tool to reset and lock the self adjusting pressure plate while you install it. Otherwise the clutch wont work properly.

So leave that centerpiece in place until everything from the clutch is installed.

This is also all described in TIS.

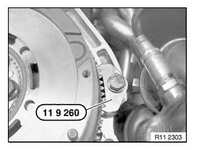

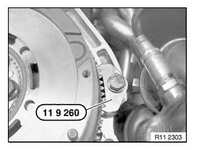

The (BMW) blocking tool for the dmf looks like this:

And it holds the flywheel in place while you loosen up the dmf bolts.

There are generic ones for sale, either as a screw in block (like the bmw tool) or hand held ones, that look like a hook spanner.

I don't know how good either of those work, I didnt have to replace my dmf.

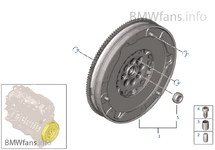

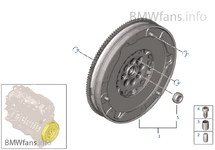

The dmf bearing is a small needle roller bearing that sits inside the dmf. Thats where the prise axle (input axle) from the gearbox goes.

Part number 5:

So its not the clutch release bearing.

I suspect that that dmf roller bearing comes preinstalled with your dmf.

As for a clutch locator tool, you need something that fits into that small dmf roller bearing, and then widenes to the clutch centerhole plate.

I think I used an e10 socket and put that into a 15mm socket with tape around it etc. You know, the usual fiddeling.

This is the bmw tool/method:

http://bmwmag.com/?tag=clutch-alignment-tool

Also used in this video:

https://www.youtube.com/watch?v=8qZskpXW9t4

(if you fall asleep by the monotone voice you'll miss it, it's at the end....)

If you dont get a new pressure plate and new clutch plate (for example just replace clutch plate and keep the old pressure plate) you need a special tool to reset and lock the self adjusting pressure plate while you install it. Otherwise the clutch wont work properly.

So leave that centerpiece in place until everything from the clutch is installed.

This is also all described in TIS.

The (BMW) blocking tool for the dmf looks like this:

And it holds the flywheel in place while you loosen up the dmf bolts.

There are generic ones for sale, either as a screw in block (like the bmw tool) or hand held ones, that look like a hook spanner.

I don't know how good either of those work, I didnt have to replace my dmf.

The dmf bearing is a small needle roller bearing that sits inside the dmf. Thats where the prise axle (input axle) from the gearbox goes.

Part number 5:

So its not the clutch release bearing.

I suspect that that dmf roller bearing comes preinstalled with your dmf.

As for a clutch locator tool, you need something that fits into that small dmf roller bearing, and then widenes to the clutch centerhole plate.

I think I used an e10 socket and put that into a 15mm socket with tape around it etc. You know, the usual fiddeling.

This is the bmw tool/method:

http://bmwmag.com/?tag=clutch-alignment-tool

Also used in this video:

https://www.youtube.com/watch?v=8qZskpXW9t4

(if you fall asleep by the monotone voice you'll miss it, it's at the end....)

Yes or maybe something cheap like this works too

http://www.ebay.co.uk/itm/Flywheel-Locking-Holding-Tool-FITS-CITROEN-BERLINGO-RELAY-SYNERGIE-1-9D-TD-/361052462298

Not specific for bmw but I think the teeth are all pretty much the same.

Other generic ones I know are like these:

http://www.ebay.de/itm/Schwungrad-Arretierwerkzeug-Schwungscheibe-Arretierung-Kurbelwelle-Kfz-Werkzeug-/400427605918

or this vw tool

http://www.ebay.co.uk/itm/VW-CAMPER-FLYWHEEL-LOCKING-TOOL-LOCK-T2-Type-2-bus-bay-split-NEW-/181847132000

I wouldnt use the tdc locking hole (near the starter motor) to lock the flywheel with a tdc pin, because of the torque required on the flywheel bolts.

http://www.ebay.co.uk/itm/Flywheel-Locking-Holding-Tool-FITS-CITROEN-BERLINGO-RELAY-SYNERGIE-1-9D-TD-/361052462298

Not specific for bmw but I think the teeth are all pretty much the same.

Other generic ones I know are like these:

http://www.ebay.de/itm/Schwungrad-Arretierwerkzeug-Schwungscheibe-Arretierung-Kurbelwelle-Kfz-Werkzeug-/400427605918

or this vw tool

http://www.ebay.co.uk/itm/VW-CAMPER-FLYWHEEL-LOCKING-TOOL-LOCK-T2-Type-2-bus-bay-split-NEW-/181847132000

I wouldnt use the tdc locking hole (near the starter motor) to lock the flywheel with a tdc pin, because of the torque required on the flywheel bolts.

GuidoK said:Yes or maybe something cheap like this works too

http://www.ebay.co.uk/itm/Flywheel-Locking-Holding-Tool-FITS-CITROEN-BERLINGO-RELAY-SYNERGIE-1-9D-TD-/361052462298

Not specific for bmw but I think the teeth are all pretty much the same.

Just to keep anyone else in the loop who is considering doing this job. The above tool does not fit directly. I will modify it slightly with the angle grinder so that it does fit. Without this though the teeth are just not spread out enough. Thanks for the help still Guidok.

http://www.z4-forum.com/forum/viewtopic.php?f=7&t=85972

just saying

just saying

Similar threads

- Replies

- 7

- Views

- 148

NO LONGER NEEDED

Wanted E85 3.0si Manual

- Replies

- 8

- Views

- 909

- Replies

- 10

- Views

- 333

- Replies

- 6

- Views

- 384

- Replies

- 0

- Views

- 145