This is more marketing embellishment than complex engineering. To say that this product is "optimised" for a variety of vehicles and a wide variety of users with different size hands and personal preferences just isn't really possible. I'm not knocking the product itself - I'm a big fan of my Stormwerks V1, but I wouldn't be suckered in to believing all their claims...thanatu55 wrote: ↑Sat Mar 31, 2018 8:20 pm"This shift knob is the result of extensive development, from its size and shape, to its weight. (Please scroll down).Davz wrote: ↑Sat Mar 31, 2018 8:12 pm so how do you know there is science behind the design of a gearknob?

Please only make statements that you can quantify or it looks like you are belittling the efforts of a skilled and knowledgable engineer with no credentials of your own.

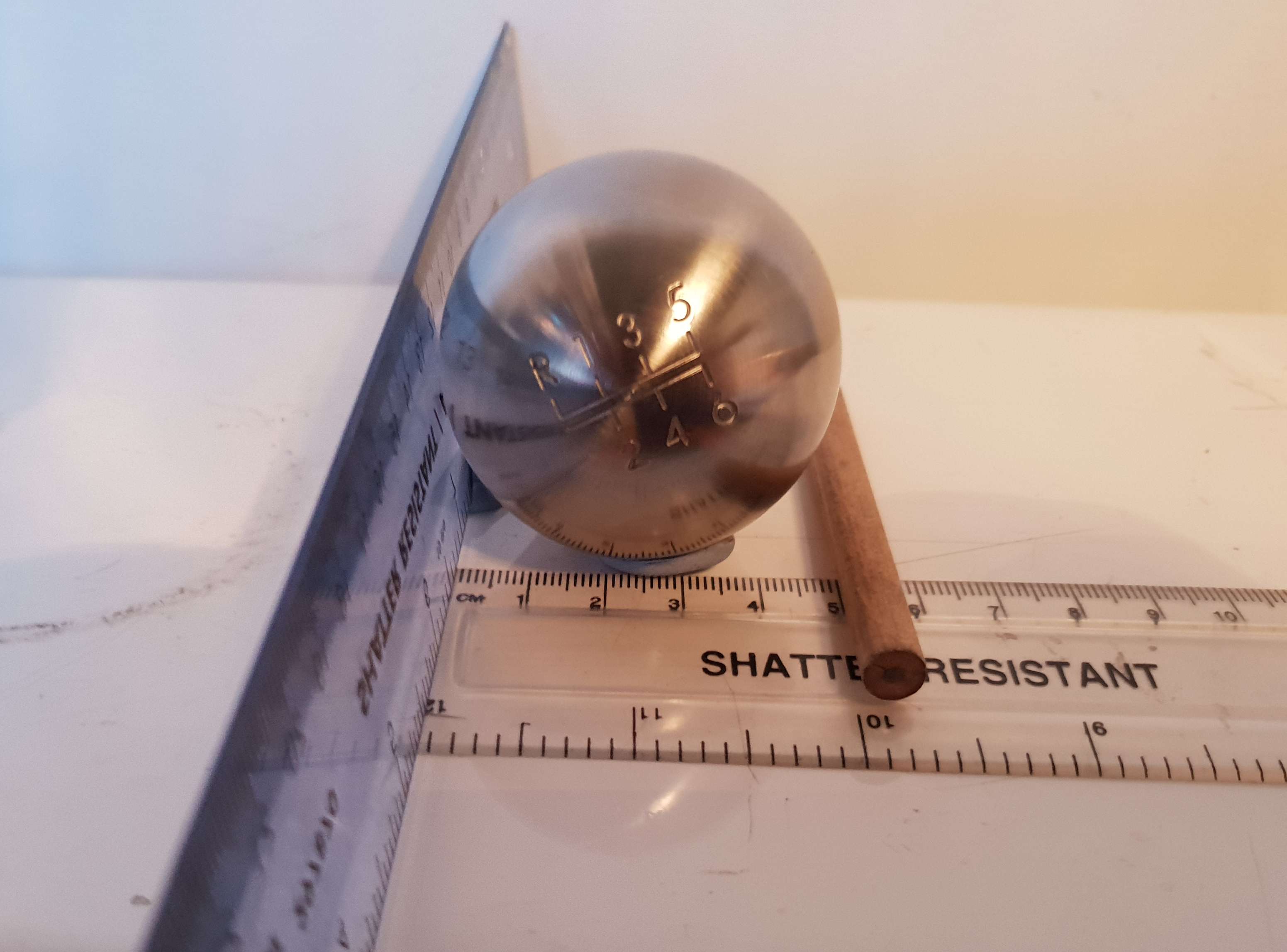

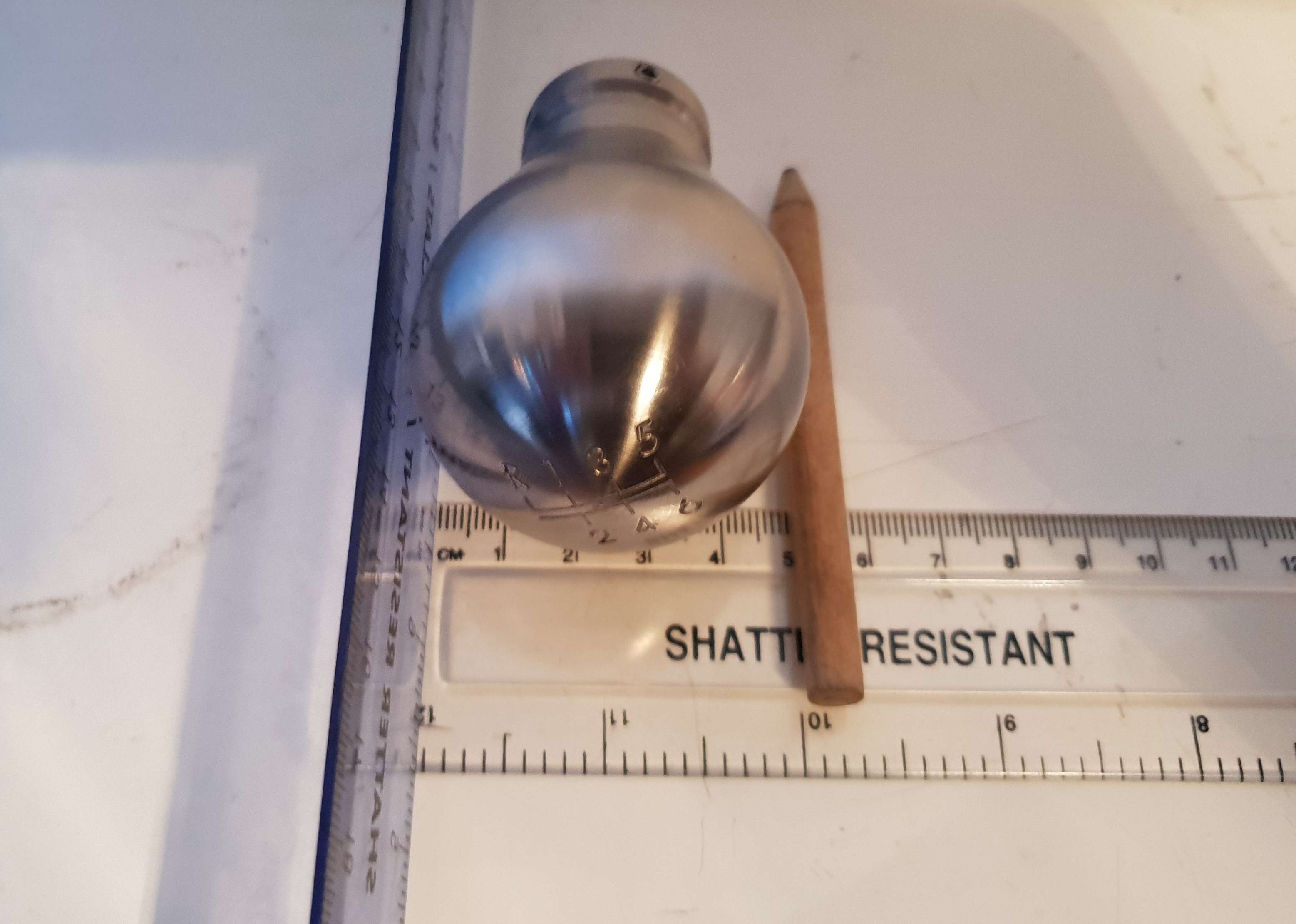

On the plus side, that was really good of you to take the photo's of your knob against the plastic rule....chapeau!

CNC precision machined from Stainless Steel billet and fully optimised for an improved gear change. This is NOT the usual aftermarket gear knob - this is a fully engineered solution to improve your overall driving experience.

Weight

Weighing in at just over 500g, the stainless steel shift knob really does feel substantial. The "notchy" nature of the BMW gearboxes is significantly smoothed out with this weight through providing a greater pivot force, giving you an effortless and precise gear change every time. Prototyping revealed that with the shift knob too light - the notchiness would still be there, too heavy and gearchange would become laboured and sloppy. With the weight optimised, we have met both criteria - smooth and swift.

Size & Shape

The standard shift knob sits at an awkward height - for both ergonomic and aesthetic purposes. Our aim was to optimise the height for reduced throw and a more natural feel. Prototyping revealed that if it sat too low - users would grip the shifter with fingertips rather than the palm of the hand. This was more apparent with cars having centre arm-rests. Iteration resulted in an optimum height, correcting both aesthetic and ergonomic problems of the standard position. Furthermore, by merging a 2" sphere with a cone, every gear-change technique is accommodated for with an intuitive grip.

Short Shift Kits

This shift-knob is an ideal add-on to a factory or aftermarket short shift kit. Such kits increase the resistance during gearchange - amplifying the inherent notchiness but our shift knob allows you to have the benefits of your short shift kit without this extra resistance. "

Ahem.

Not joined yet? Register for free and enjoy features such as alerts, private messaging and viewing latest posts and topics.

Custom gear knob

- C8H18

- Member

- Posts: 77

- Joined: Fri Jul 28, 2017 9:40 pm

- Location: Somerset

Custom CNC machined stainless steel Gear Knob

2006 silver / muddy 3.0si roadster manual

- Chris_D

- Lifer

- Posts: 6615

- Joined: Thu Apr 21, 2016 11:41 pm

- Location: Mostly Holland. Sometimes UK.

Custom CNC machined stainless steel Gear Knob

As a former nuclear and aerospace design engineer I have to admit to the left half of my mouth changing shape when I read Stormwerks rather flowery description of their 'extensively developed' gearknob.thanatu55 wrote: ↑Sat Mar 31, 2018 8:20 pm"This shift knob is the result of extensive development, from its size and shape, to its weight. (Please scroll down).Davz wrote: ↑Sat Mar 31, 2018 8:12 pm so how do you know there is science behind the design of a gearknob?

Please only make statements that you can quantify or it looks like you are belittling the efforts of a skilled and knowledgable engineer with no credentials of your own.

On the plus side, that was really good of you to take the photo's of your knob against the plastic rule....chapeau!

CNC precision machined from Stainless Steel billet and fully optimised for an improved gear change. This is NOT the usual aftermarket gear knob - this is a fully engineered solution to improve your overall driving experience.

Weight

Weighing in at just over 500g, the stainless steel shift knob really does feel substantial. The "notchy" nature of the BMW gearboxes is significantly smoothed out with this weight through providing a greater pivot force, giving you an effortless and precise gear change every time. Prototyping revealed that with the shift knob too light - the notchiness would still be there, too heavy and gearchange would become laboured and sloppy. With the weight optimised, we have met both criteria - smooth and swift.

Size & Shape

The standard shift knob sits at an awkward height - for both ergonomic and aesthetic purposes. Our aim was to optimise the height for reduced throw and a more natural feel. Prototyping revealed that if it sat too low - users would grip the shifter with fingertips rather than the palm of the hand. This was more apparent with cars having centre arm-rests. Iteration resulted in an optimum height, correcting both aesthetic and ergonomic problems of the standard position. Furthermore, by merging a 2" sphere with a cone, every gear-change technique is accommodated for with an intuitive grip.

Short Shift Kits

This shift-knob is an ideal add-on to a factory or aftermarket short shift kit. Such kits increase the resistance during gearchange - amplifying the inherent notchiness but our shift knob allows you to have the benefits of your short shift kit without this extra resistance. "

Ahem.

Ahem.

I don't question that weight, size, shape and mounting position play an important part for the end-user and to that extent, simply trying a number of different sizes, shapes and possibly materials would help to determine a useable/marketable product.

But I doubt very much whether any destruction-testing, thermodynamic analysis, FMEA, FMECA, FEA, stress analyses or any other form of 'extensive development' methodology, as I would normally expect when I hear that description used, has played any part in this. I suggest the marketeers have had a chat with the design engineers at some point. 'Aye lads, what would sound good on our website if we wanted to market this as a precision-engineered bit of kit? Whatdya reckon?'

E85 3.0i roadie (03) 'Benny'. E93 320d M-Sport Cabrio (11) 'Bob'.

'Always different, always the same.' John Peel on The Fall.

'Always different, always the same.' John Peel on The Fall.

- thanatu55

- Senior Member

- Posts: 1452

- Joined: Mon Jul 25, 2016 4:50 pm

Custom CNC machined stainless steel Gear Knob

My point is that research and development has been undertaken rather than placing a ball on a stick. That was the question posed to me and I quantified it with an answer. Marketing speak aside, the point stands.

All I said was that simply copying a shape doesn't make it the equal in all aspects of the other, then Billy Big B*****ks wanted more information and I obliged.

All I said was that simply copying a shape doesn't make it the equal in all aspects of the other, then Billy Big B*****ks wanted more information and I obliged.

Last edited by thanatu55 on Sat Mar 31, 2018 8:55 pm, edited 1 time in total.

- C8H18

- Member

- Posts: 77

- Joined: Fri Jul 28, 2017 9:40 pm

- Location: Somerset

Custom CNC machined stainless steel Gear Knob

Truly, not a great deal, albeit likely more than many. They admit to using iteration to achieve the result they wanted - an impressive sounding term which simply means trial and error.

Nice end product? Yes.

Complex, precision engineering? Not so much.

2006 silver / muddy 3.0si roadster manual

- Chris_D

- Lifer

- Posts: 6615

- Joined: Thu Apr 21, 2016 11:41 pm

- Location: Mostly Holland. Sometimes UK.

Custom CNC machined stainless steel Gear Knob

I made a comfy catbox last week. somewhere nice and warm that the visiting kittykat could chillax when he comes over to my gaff for a visit.

My research and development phase consisted of taking his physical measurements and seeing what material I could line it with that would keep him cosy and comfortable.

Admitted, not the most scientific r&d but still....it was a legitimate, well thought-out r&d exercise leading to an exceptionally well-received end-user product.

My research and development phase consisted of taking his physical measurements and seeing what material I could line it with that would keep him cosy and comfortable.

Admitted, not the most scientific r&d but still....it was a legitimate, well thought-out r&d exercise leading to an exceptionally well-received end-user product.

E85 3.0i roadie (03) 'Benny'. E93 320d M-Sport Cabrio (11) 'Bob'.

'Always different, always the same.' John Peel on The Fall.

'Always different, always the same.' John Peel on The Fall.

- thanatu55

- Senior Member

- Posts: 1452

- Joined: Mon Jul 25, 2016 4:50 pm

Custom CNC machined stainless steel Gear Knob

Refer to my edited quote, the initial statement was that copying by eye doesn't make all things equal. Can this statement be proved by science?... yes. The spiel is irrelevant.

I was actually trying to be helpful by providing further information on a product that by it's manufacturers own admission is an attempt to replicate another.

Is this going to drag on all night? The boxing is on and my one statement is not worth all this p****ng about.

- C8H18

- Member

- Posts: 77

- Joined: Fri Jul 28, 2017 9:40 pm

- Location: Somerset

Custom CNC machined stainless steel Gear Knob

Sorry, thanatu55 - I wasn't meaning to have a pop at you, more amusement at the hyperbole on the Stormwerks website. I can see that you were trying to help out a fellow forum member, and that's always a good thing.

Enjoy the boxing

Enjoy the boxing

2006 silver / muddy 3.0si roadster manual

-

Buckley06

- Member

- Posts: 499

- Joined: Mon Feb 05, 2018 9:17 pm

Custom CNC machined stainless steel Gear Knob

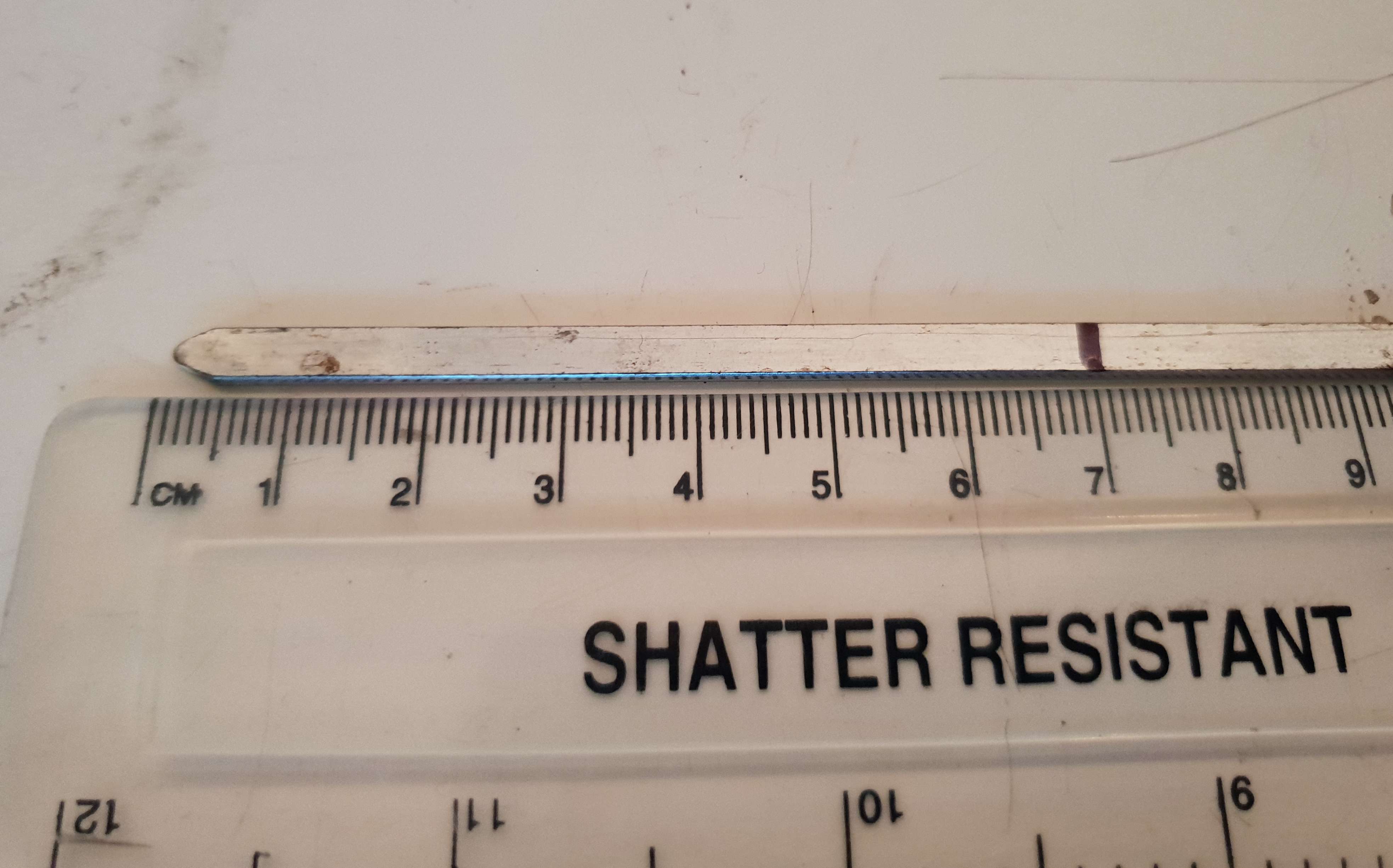

Thank you for the pics mine is not to far out 50mm od 75mm long and 65 deep on the 14mm hole.

But I can do a quick shape change on Tuesday.

I will give it to my new friend chris_D and he will do some awesome rendering on it I'm sure.

You have all been helpful regardless of the science or jargon that stormweks has done.

This is a z4 only gear knob and one you can't get in the shop and has input from like minded z4 fans.

So as a matter of fact they are priceless as it's being made by people that care not to make overheads look good.

Please keep that in mind that you are buying a z4 custom gear knob not a replica of something from the USA.

Thank you for everyone's support I have enough people wanting one now so I will order the material on Tuesday.

Quoting the Beatles

Peace and love

- Chris_D

- Lifer

- Posts: 6615

- Joined: Thu Apr 21, 2016 11:41 pm

- Location: Mostly Holland. Sometimes UK.

Custom CNC machined stainless steel Gear Knob

Looks great!

Can't wait to receive mine.

Not sure if I want something engraved or just totally clear. I'll let u know.....

How do you want paying?

Can't wait to receive mine.

Not sure if I want something engraved or just totally clear. I'll let u know.....

How do you want paying?

E85 3.0i roadie (03) 'Benny'. E93 320d M-Sport Cabrio (11) 'Bob'.

'Always different, always the same.' John Peel on The Fall.

'Always different, always the same.' John Peel on The Fall.

- C8H18

- Member

- Posts: 77

- Joined: Fri Jul 28, 2017 9:40 pm

- Location: Somerset

Custom CNC machined stainless steel Gear Knob

Buckley06 - I've got some digital vernier calipers at home so can give you accurate dimensions for the Stormwerks V1 when I get back home next Tuesday if you like. I might measure the standard and ZHP knobs while I'm at it...

2006 silver / muddy 3.0si roadster manual

- thanatu55

- Senior Member

- Posts: 1452

- Joined: Mon Jul 25, 2016 4:50 pm

Custom CNC machined stainless steel Gear Knob

I think "Helter Skelter" is more appropriate at this point lol.

In all seriousness I wasn't looking to get into a petty squabble, I'm more annoyed that it's cost me £17 for the boxing and I've spent about £10 worth of that in tit for tat.

The gear knob is great, the concept is great, the guesture is noble, the forum is happy, I'm happy...

I'm keeping out of it.

-

dans6490

- Member

- Posts: 978

- Joined: Mon Apr 14, 2014 10:28 am

Custom CNC machined stainless steel Gear Knob

If I hadn’t just bought a ZHP, I would’ve had one of these.

Love the bespoke, one-off side but also how it’s made.

If you can etch the numbers etc after they’ve been made and people can see the finished item, I would say you’ll have no problem selling them

Love the bespoke, one-off side but also how it’s made.

If you can etch the numbers etc after they’ve been made and people can see the finished item, I would say you’ll have no problem selling them

-

keith777

- Member

- Posts: 56

- Joined: Tue Nov 01, 2016 12:59 am

Custom gear knob

Put me down for one please

Cheers Keith.

Cheers Keith.

-

Buckley06

- Member

- Posts: 499

- Joined: Mon Feb 05, 2018 9:17 pm

Custom gear knob

Sure can you inbox me please with if you want plain or engraved 6 or 5 speed.

I only ask for in boxing so I can keep track of who wants one.

- Chris_D

- Lifer

- Posts: 6615

- Joined: Thu Apr 21, 2016 11:41 pm

- Location: Mostly Holland. Sometimes UK.

Custom gear knob

Might be a good idea to have a running list of who's signed up and available slots left...

While I'm here I have made an executive decision; I would like no engraving on mine please....just clear....pure....simple...nadda...noffink. lol

E85 3.0i roadie (03) 'Benny'. E93 320d M-Sport Cabrio (11) 'Bob'.

'Always different, always the same.' John Peel on The Fall.

'Always different, always the same.' John Peel on The Fall.