After installing 4/64Gb Android on Toyota Corolla (Teyes from Aliexpress) for my wife I decided to do refresh also fom my Z4 E85 2008.

As Teyes was not available with good configuration for BMW, purchased

Junsun V1 Pro 6/128Gb (Junsun Global Store on Aliexpress).

Z4 version was not available so I purchased BMW X3 E83 version. Monitor fits 90% perfectly.

It was required to cut little bit more space for rear holders of monitor holder and extend location of front screws. I simply mounted 2x5cm Alu plates to monitor with monitor screws and drilled new holes in alu plate for original BMW monitor holder screws).

- 20210722_015917_lq.jpg (35.29 KiB) Viewed 12614 times

- 20210722_015942_lq.jpg (24.71 KiB) Viewed 12614 times

- 20210722_020438_lq.jpg (30.72 KiB) Viewed 12614 times

To have 100% perfect view you can cut with dremmel and polish (maybe also paint) front lip of monitor plate, but I am perfectly fine with current look.

Original wiring from X3 is plug and play. Of course before connecting I double checked with spec of Z4 connector and double checked location of power wires: battery, acc, illumination etc.

Current progress and challenges:

Canbus works perfectly - used option 85 "MW MINI FSTT 85" (option 65 BMW MINI was not available) in canbus setup menu.

1. Buttons on wheel are working perfectly and can be assinged for different options.

2. Rear camera turns on the monitor, after switching rear gear. Camera is not connected yet in my setup (ordered better AHD 1080p one), but Android catches rear gear signal and switches monitor to rear camera well.

Sound:

Sound generally is goob, but as unit is having amplifier and BMW is having amplifier there is double amplifier challenge. Ordered now Hi To Low 4 channel converter. Linear output can be used for the same purpose, but I decided to go for Hi Low first.

Ordered Radio Wire extension from the same store to do not cut orignal wire and to inject Hi Low converter in speaker outputs on extension wire.

Challenge with general volume. Currently volume is too independant. There is seperate volume for Nav, for BT, for Music/Radio etc. Volume difference is adjusted in engineering menu, but there is not kind of Master Volume. For example if volume is decreased for Radio, Nav continues to operate on its own volume and can be adjusted by volume button only in the moment NAV speaks. I need to find good app to handle it.

Video. Rear camera is good as mentioned. AHD 1080p supported. Not installed yet.

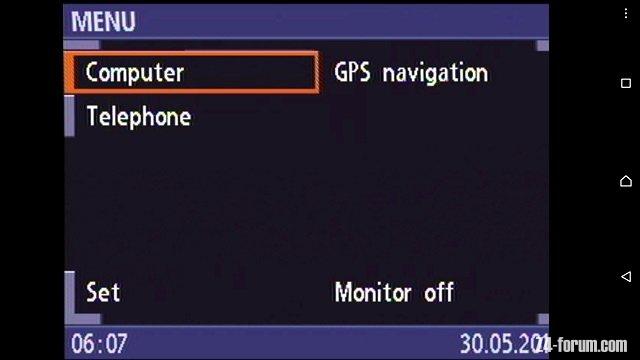

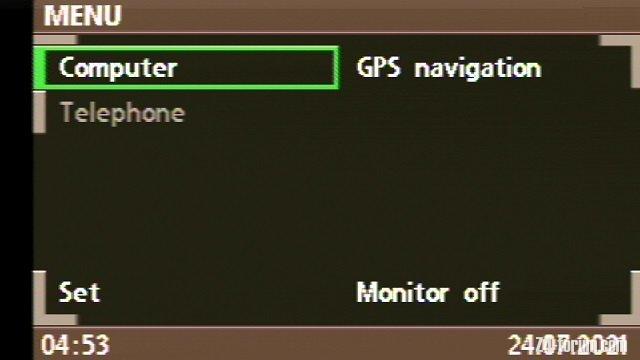

CVBS In is not as expected (to display board computer menu - not really reuqired, but let it be). Probaly its in PAL format. I am reusing Ambery device + LM1881 used in previous Android tabled integration described in the previous pages of this forum. Simple NTSC/PAL video screen for 10EUR worked perfectly with this signal.

Previous setup OK (EasyCap utv007):

- BMW_CID_expected_easyCap_utv007_NTSC_lq.jpg (20.73 KiB) Viewed 12614 times

Current one:

- BMW_CID_v1_pro_cvbs_in_lq.jpg (21.96 KiB) Viewed 12614 times

Ordered PAL NTSC mini converter from Aliexpress to fix this, hope it will work.

Software:

Root access ok.

Challenges with original firmware, for example unit resets some settings and main screen after changing value in engineering menu etc. This is reported to manufacturer. Hope it will be resolved soon.

Summary:

New Android refreshed car for -10years. Its really nice to have fast operating Android onboard with 9" screen, good Nav (Waze), Youtube, Spotify, Internet etc. There are pending challenges but 6/128Gb Android 10 hardware is good starting point.

- 20210724_051939_lq.jpg (106.12 KiB) Viewed 12614 times

- 20210724_051925_lq.jpg (101.52 KiB) Viewed 12614 times

Current Costs:

Junsun V1 Pro 295EUR

1080p AHD cam 24EUR

Hi Low coverter 4ch 11EUR

Radio Extension Wire 4EUR

NTSC<-->PAL coverter 8EUR